Machining

HMCs Improve Unattended Machining Performance

IMTS 2024: JTEKT’s FH5000 HMC with pallet pool expands the capability for more flexible production for shops of any size, such as the processing of multiple mold and dies as needed.

Read MoreSpeed Increasers Promote High Spindle Speeds for Handling Thick, Large Workpieces

Platinum Tooling is now supplying this additional equipment from Henninger to North America, useful for drilling, tapping and milling mold applications, among others.

Read MoreComprehensive Deep-Hole Drilling Support Multiple Manufacturing Operations

IMTS 2024: Unisig’s full range of deep-hole drilling applications, paired with its engineering, sales and service support, provide a breadth of technology coverage for mold and die, automotive and other industries.

Read MoreDouble Column VMC Designed With Large Mold Machining in Mind

Kitamura introduces the Bridgecenter-6G, targeting large, long parts with a highly rigid design, taper versatility and customizable controls.

Read MoreHow to Achieve Unmatched Accuracy in Very Large Workpieces

Dynamic Tool Corp. purchases two bridge-style double-column CNCs to increase the cutting envelope and maintain 5-micron cutting accuracy in the long term.

Read MoreGantry Machines Handle Diverse Machining Applications

The Soraluce High Rail Gantry Machines offer high-speed cutting capabilities, high precision rates and handling of high-volume machining tasks for mold and die and other sectors.

Read MoreTriple Threat: How One Shop's Success Resonates Across Three End Markets

When I revisited Eden Tool in New Freedom, PA, this past summer for a follow-up feature on this mold builder’s growth, I underestimated the story.

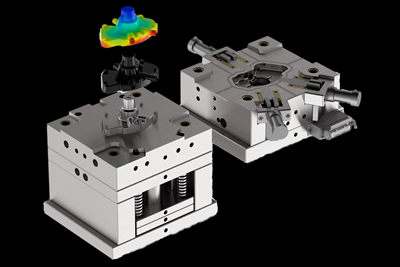

Read MoreTips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

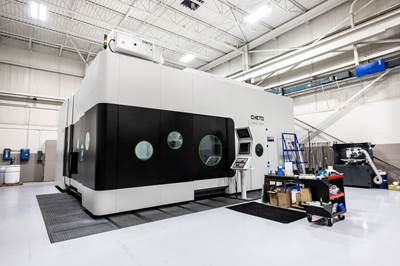

Read MoreCentury Tool Invests in Cheto Machine for Deep-Hole Drilling With Milling

Seven-axis CNC strings together gundrill and milling programs, enhancing Century Tool’s moldmaking process.

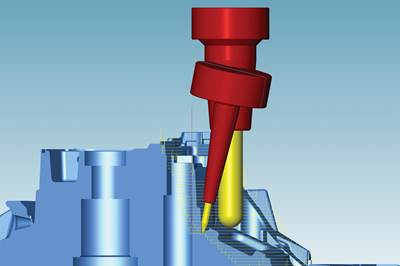

Read MoreHow to Implement Five-Axis Mold Machining for Higher Productivity, Versatility

Understanding the basics of five-axis capabilities justifies the investment, but exploring all the multi-axis machine benefits and approaches enhances the return on investment.

Watch

.jpg;maxWidth=300;quality=90)