Machining

Gundrill Production Cells Boost Precision, Output

The Unisig R-4-2-2 production cell uses a smart conveyor to simultaneously load four barrel blanks into a UNI four-spindle gundrilling machine.

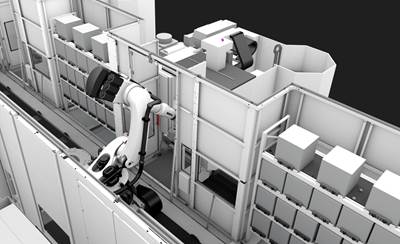

Read MoreUsing Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

Read MoreVMC Provides Versatile Machining of Complex Parts

The Mazak North America VC-Ez 20X vertical machining center features a 25-horsepower 12,000-rpm CAT-40 spindle with a 30-tool-magazine automatic toolchanger.

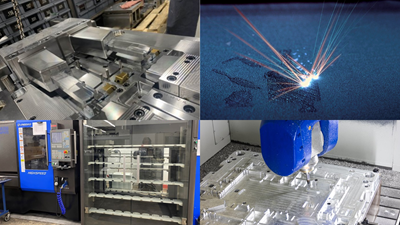

Read MoreHybrid Multitasking Five-Axis Brings Subtractive, Additive Processes to Moldmakers

Mazak’s VC-500A/5X vertical machining center delivers hybrid multitasking and hot wire deposition to meet machining and additive needs.

Read MoreHow to Use and Protect Remote Machine Monitoring Data

Collecting, analyzing and securing machine data in real time can substantially improve productivity, profitability and customer satisfaction.

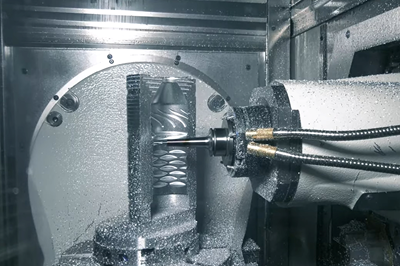

Read MoreSpace-Saving Five-Axis Provides Productive Mold Machining

The Grob G150 universal machining center and its spatial accuracy enhances its performance with complex, high-precision components.

WatchMoldMaking Technology's Most-Viewed Case Studies of 2023

MoldMaking Technology’s case studies present a shop’s problem, solution and results in thorough detail. Take a look at our top five most-viewed case studies based on Google Analytics.

Read MoreDynamic Milling Machine Design Improved for Heavy Machining

Zimmerman modifies its five-axis FZU/FZP42 machine line with features like a thermo-symmetrical design and centrally guided Z-slide to efficiently process large workpieces more dynamically and productively.

Read MoreMoldMaking Technology's Hottest Tips of 2023

The staff at MoldMaking Technology prides ourselves on bringing you the most helpful, relevant tips in the industry. Here are the top five most-viewed tips of 2023 based on Google Analytics.

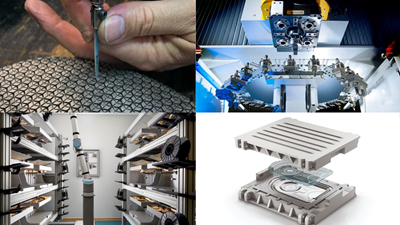

Read MoreMachine Tool Considerations for Today's Mold Builder

Machine rigidity, spindle speed, power and control options that run complex programs smoothly are vital to meet the industry’s surface finish and speed requirements.

Read More

.jpg;maxWidth=300;quality=90)