Leadership

Help in Getting Projects Off the Ground

Today there is no lack of creativity when it comes to companies thinking outside the box on ways to market themselves more effectively and better serve new and existing customers. Sometimes it's in the form of a new collaboration or added service, and sometimes it's creating an internal program to assist entrepreneurs looking to get a project off the ground using plastic injection moldmaking and molding.

Read MoreClose Collaboration with Customer Results in Successful Overmolding Process

The mold Roembke Mfg. & Design designed and built for the vial for a water test cartridge is single drop cold deck with a standard LSR valve gate design featuring side injection versus back injection for the plastic.

WatchThe Primary Strengths and Weaknesses of the U.S. Economy

Studying, analyzing, and forecasting the North American moldmaking industry for the past 20 years has taught me a lot. It has deepened my understanding of things such as innovation, initiative and industriousness. But the most important thing I have learned, is the meaning of “competition.”

Read MorePrecise Military Parts On Demand

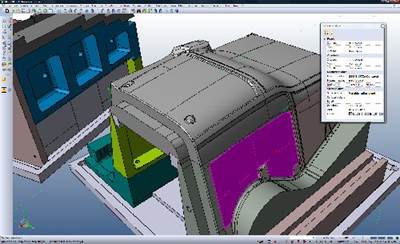

EADS Innovation Works combines 3D imaging/reverse engineering software with additive manufacturing technology to demonstrate a quicker, more cost-effective method for providing replacement parts for military vehicles and equipment in the field.

Read MoreMotorola RP Services: 20,000 Electrodes and Counting

Motorola has placed an increased emphasis on adding new software tools to improve its engineering and manufacturing operations. For its moldmaking business, this has meant implementation of new procedures in Cimatron-E and implementation of a Hexagon PC-DMIS solution on the shop floor.

Read MoreCommunication and Creativity Paramount in Tooling Supplier/Molder Relationship

This custom molder looks for creativity, reliability and a proven track record before it hires a tooling supplier.

Read MoreEDM Efficiencies Excel

Advancements in EDM processes in terms of machining speed and surface finish improve overall accuracy, productivity and profitability.

Watch"Adding" onto the Manufacturing Strategy

Earlier this month at IMTS--The International Manufacturing Technology Show 2012--The Association For Manufacturing Technology made available its second generation of The Manufacturing Mandate, which emphasizes collaboration as a crucial element to solidifying the renaissance in American manufacturing. One such recent collaboration involves additive manufacturing.

Read MoreDesign Collaboration Produces Tooling Right First Time

DeltaCAD Ltd collaborates with sub contract tooling manufacturer Casting Support Systems on a project to provide a leading aerospace company with aluminum tooling for a carbon composite seat shell for a major civil airline company.

Read MoreCylindrical Drive Technology Adds Efficiency to EDM Operations

New system only exposes half of the magnetic flux to the face of the coils.

Watch