Grinding

Extreme Tool and Engineering: Building Relationships, Fostering Growth

This moldmaker proves that dedication to its customers combined with a will to thrive in a global marketplace is the right formula to win the MoldMaking Technology 2006 Leadtime Leader Award: Large Shop.

Read MoreMatch Cutting Tools To Machine for Maximum Efficiency

A large range of tooling enables moldmakers to match cutting tool to machine and part geometry, resulting in maximum metal removal rates and productivity for roughing applications on conventional and high-speed machining centers.

Read MoreTechnology and Skill Are Keys to Mold Shop Success

In a driven and changing mold industry, a secret weapon has helped one mold shop to excel and grow.

Read MoreHSM Equals Accuracy and Precision at Less Cost

A California moldmaker makes the most of state-of-the-art machine tool and design technology to deliver competitive advantages for a medical device customer.

Read MoreEquipment Leasing: A Popular Alternative to Buying

Leasing equipment provides moldmakers with more purchasing opportunities during tough financial times.

Read MoreHow to Control Excessive Tool Wear

By calculating feeds and speeds properly, moldmakers can reduce tooling costs, have less machine downtime and see less scrap due to worn tools.

Read MoreChoosing a High-Speed Spindle for Moldmaking

Many factors - such as mounting style and lubrication choices - need to be considered when choosing a high-speed spindle.

Read MoreKing Systems, Plastics Technology Division - Developing A Competitive Edge Never Ends

By investing in both technology and employee skills, King Systems, Plastics Technology Division, combines the customer service advantages of a small-sized moldmaker with the cutting-edge skills needed to succeed.

Read MoreMoldmaker-Invented Chiller Keeps Workpieces Cool Without External Coolants

A quest to improve the dry grinding process yields a chilling system that improves accuracy and increases production.

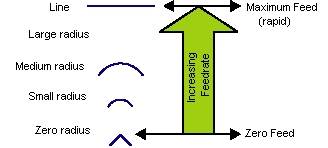

Read MoreBecoming More Accurate With Speed

By adding optimization software to their machining, moldmakers will be able to produce better quality parts with better accuracy.

Read More