FAQ

Establishing an Industry Edge

One mold shop has found a way to compete and win against overseas outsourcing.

Read MoreHow to Sell in a Changing World

In today's increasingly competitive world, focusing on the customer's needs may be the greatest advantage moldmakers have to staying in the game.

Read MoreSPECIAL FEATURE: Education/Training - Tailored Training Is the Best Way to Build Effective Manufacturing Teams

On-the-road training brings together owners, managers, programmers and operators in one classroom to develop a team-building process.

Read MoreMake Way for Change

Moldmakers can increase their chances of success by forming a strategic plan, adapting to industry change and seeking new ways to address growth.

Read MoreHow to Prevent Mold Inaccuracies

By keeping compressed air dry, moldmakers can prevent damage to critical equipment.

Read MorePart One of a Two-Part Series Motivating and Training Your Employees

Trust, knowledge and technical training help to motivate employees and guarantee your shop's success.

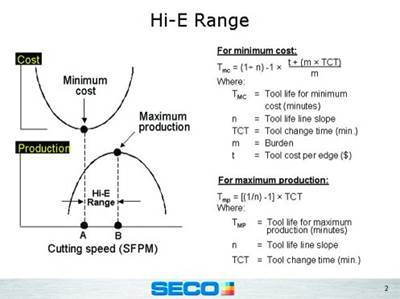

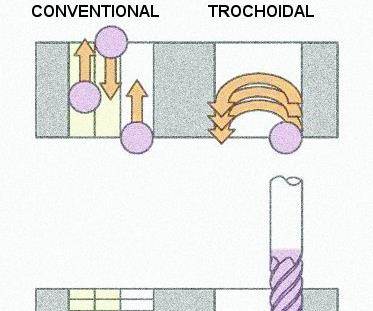

Read MoreWhat To Consider When Thinking About Solid Carbide End Mill Machining

The selection of geometries and coating for solid carbide end mills can be a confusing, but evaluating the operation will determine which end mills are best for the job.

Read MoreHow to Choose the Right Welding Option

When comparing microscopic laser welding and microscopic TIG welding, both have distinct advantages and disadvantages.

Read MoreHow to Use Indexable Tooling to Optimize Finishing Operations

High-quality indexable insert end milling systems offer moldmakers considerable cost-advantages for many finishing operations.

Read MoreQuick Math for Cylinder Calculations

Simple cylinder calculations provide good first look comparisons for proper sizing when moldmakers are considering the most suitable side-action option early in the mold design.

Read More