FAQ

In-Mold Labeling Looks to High-Output Molds for Growth

Moldmakers seek to combine ultrafast cycles and high-speed automation in tool designs.

Read MoreHow to Choose the Correct Ejector Pin?

The importance of working temperature during the ejector pin selection process.

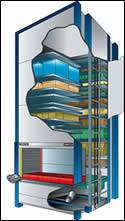

Read MoreSelecting a Vertical Storage And Retrieval System for Moldmaking Applications

Vertical systems, when properly planned and integrated into daily operations, can significantly reduce operating costs.

Read MoreHow to Gain a Better Understanding of the Complete Business Case Impacting the Tooling Purchase

By starting with five key business strategies, a structured process will identify how you can evaluate where you are today, the opportunities to improve and the factors that significantly impact your ability to compete.

Read MoreSelecting a Carbide End Mill for Aluminum Applications

Specific geometries and characteristics of a carbide end mill are required for efficient machining of aluminum.

Read MoreGetting to Know Your Machine Tool

A review of the six core components of a machine tool: automatic toolchanger, motor/drive/encoder, base casting, OSP control, turret and spindle.

Read MoreHow to Achieve Economical Five-Axis Milling

Although moldmaking has not had great incentives to invest in five-axis technology like the aerospace industry, there are still many reasons for moldmakers to adopt five-axis machining, and there are a few interesting software functions that help to make five-axis programming economical.

Read MoreHow to Solve Common Inventory Management Problems Related to Tooling

A practical look at what to consider when purchasing client/server inventory management software and how to implement such a program, as well as why and how it can benefit mold manufacturing operations.

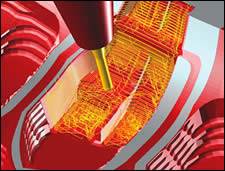

Read MoreHow to Increase Polishing Efficiencies

A concurrent approach to polishing increases the man-and-machine efficiency while streamlining workflow to help attain ever-decreasing leadtimes.

Read MoreHow to Make “Quick-Turn” Your Shop’s Mantra

On top of increasing production capacity, quick delivery standards save as much as five hours per project for a manufacturer of quality “quick-turn” tooling.

Read More