Selecting a Vertical Storage And Retrieval System for Moldmaking Applications

Vertical systems, when properly planned and integrated into daily operations, can significantly reduce operating costs.

Handling materials in a typical injection molding operation can account for a large percentage of production time, and the movement and storage of molds and tooling can represent a significant portion of the cost of production.

A solution to more efficient storage, handling and retrieval of materials is the installation of a vertical storage and retrieval system as an alternative to conventional drawer, shelving and rack systems. Vertical systems, when properly planned and integrated into daily operations, can solve many of the problems associated with poor utilization of floor space, productivity requirements, centralized stockrooms, information and inventory management, and quick response/JIT disciplines, lean manufacturing, and six sigma initiatives. In the process, they can significantly reduce operating costs.

| Chart 1 | |||

| Ceiling Height |

Eliminated Drawer Cabinets | Space Savings (sq. ft.) |

Space Savings (percentage) |

| 15’ | 19 | 90 | 53% |

| 20’ | 28 | 158 | 66% |

| 25’ | 36 | 226 | 74% |

| 30’ | 46 | 311 | 80% |

| 35’ | 55 | 396 | 83% |

| 40’ | 65 | 481 | 86% |

| Illustrates the space saved by converting standard drawer systems to vertical storage and retrieval systems. Chart courtesy of Remstar International. | |||

Vertical storage and retrieval systems consist of two primary devices. One is called a vertical carousel that uses rotating carriers, or shelves, that move on a track in response to operator commands. Roll out drawers, totes, containers and liners can be used to access molds and items stored on each shelf.

The other vertical storage and retrieval device is a vertical lift module. Vertical lift modules consist of a series of trays that are mounted on both sides of an inserter/extractor device. Every tray is always scanned for its current height and is stored in the unit in one-inch increments. Vertical lift modules can also have their height increased or decreased to meet changing needs. This flexibility is ideal for shops that see changes in their business, processes and procedures.

With both the vertical carousel and vertical lift module, items are automatically delivered to the operator at an ergonomically positioned work counter, eliminating walking, searching, bending and stooping. Carts can be used with vertical carousels to offload molds and deliver them to the production floor. Entire trays of molds and tooling from vertical lift modules can be removed and transported by material handling vehicles.

There are vertical systems that can easily handle tools, molds and inserts. Other vertical storage and retrieval systems are designed specifically to store small tooling, raw materials used in the molding process, and consumable safety items.

Why Vertical Systems?

One of the primary reasons for considering a vertical system is the improved space utilization they offer. Depending on usable building interior heights, a significant percentage of a conventional storage system’s occupied floor space can be recovered. The small unit footprint makes vertical systems especially valuable for point-of-use storage and JIT manufacturing applications. Recovered floor space can be re-allocated from cost-associated functions of inventory to value-increasing produc-tion operations. Improved space utilization also can extend the useful life of existing facilities—eliminating the need for expensive brick and mortar expansion to meet growth requirements.

Redundant or non-essential handling can be reduced with vertical systems, especially in applications requiring frequent reuse of molds. This is particularly important since damage to molds caused by frequent handling can interrupt process flow. The time saved also results in less operating cost and usually improved customer service. Labor costs are reduced due to the system’s quick retrieval times and the capability to meet varying throughput requirements while not being bound by thresholds imposed by limited-access systems.

Conventional static storage systems like shelving require employees to spend up to 70 percent of their time traveling aisles searching for items and only 30 percent actually storing and retrieving items. Typically, using vertical storage and retrieval systems, an operator’s walk and search time is reversed from that of conventional systems to 70 percent picking and only 30 percent searching time.

The access area of vertical systems is ergonomically designed to present stored items at an ideal height for picking, usually about waist high. This location of the access area contributes to employee safety since this positioning design eliminates the bending, climbing and stretching associated with conventional shelving and rack systems. Productivity generally improves as well.

Since vertical systems are totally enclosed and lockable to protect products from external hazards and reduce die and mold damage and pilfering, inven-tories can be reduced in many opera-tions. Stock rotation can be improved by utilizing computerized picking controls.

Vertical storage and retrieval systems also offer increased picking speed and accuracy using microprocessor controls with position indicators, information displays, PC-based software, and overall system physical design.

Defining System Performance Requirements

Since vertical systems can be equipped with many variations of shelf configurations, item profiling is used to custom engineer the application to the need. For example, are the items to be stored odd-shaped or standard sizes? Are they loose, requiring a container or a tote? Weight also is a consideration. When defining system requirements, average weight density information is calculated to determine shelf or tray loading requirements.

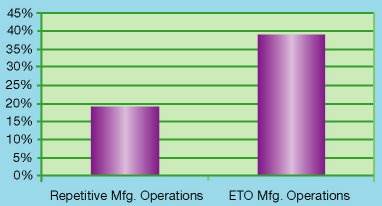

Consideration also must be given to the physical layout of the installation site. The clear height of the building interior will determine the height of the units and the total number of shelves at a given spacing allowed in each unit. For example, in a facility with a ceiling height of 40 feet, a vertical storage and retrieval system eliminates up to 100 shelving sections with a resulting space savings of up to 929 square feet, or 91 percent. With a ceiling height of 30 feet, a vertical solution can eliminate 46 drawer-type cabinets for a space savings of 311 square feet, or 80 percent (see Chart 1).

Defining Control Requirements

For functional effectiveness, transaction information must be transmitted between the operator and the control system. Vertical storage and retrieval systems can be controlled using PC software or hardware controls. A system can be configured for stand-alone, single-user operation or multi-user network use. The operator simply enters the shelf number using the controls, and the shelf and its contents are delivered automatically. Pick-to-Light and bar code scanning technology can be easily integrated to direct the operator to the proper pick location for added accuracy.

A software system can be networked to manage multiple vertical units in high throughput applications. A multi-user system provides independent operation of each unit in the network while information accessed on workstations is shared on a common database and uploaded to a host warehouse management system (WMS) or enterprise resource planning (ERP) system.

Making the Right Move

Integrated vertical storage and retrieval systems often have a return on investment (ROI) of less than 18 months. However, as with any major investment, a comparison of the costs of the new system versus the old system must be considered. For vertical storage and retrieval systems, the operative data are the amount of floor space occupied by current equipment, cost per square foot, the number of employees handling daily transactions, number of transactions performed daily, average labor cost and other information that affects system costs. Sitting down with an installation specialist and putting the numbers into a standard ROI/IRR (return on investment/internal rate of return) formula is one way to do this.

Another is to find a provider of automated storage and retrieval systems that offers the use of a special ROI/IRR calculator, which allows users to enter the appropriate data. It automatically computes the daily cost of the current system and the daily cost of the new system. The calculator also computes dollar savings from reduced space requirements, cost savings from improved employee productivity, depreciation savings and total annualized savings. From this information, the calculator helps determine the payback schedule for the user’s specific installation.

There are a number of important factors to consider when planning the installation of a vertical storage and retrieval system. A properly applied approach to planning and specifying can substantially enhance the benefits these systems offer. After you have determined what your particular storage and retrieval requirements are, using the planning approach outlined in this article, call in an expert to help you specify a system.

Related Content

Making Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreThe Trifecta of Competitive Toolmaking

Process, technology and people form the foundations of the business philosophy in place at Eifel Mold & Engineering.

Read MoreEditorial Guidelines: Editorial Advisory Board

The Editorial Advisory Board of MoldMaking Technology is made up of authorities with expertise within their respective business, industry, technology and profession. Their role is to advise on timely issues, trends, advances in the field, offer editorial thought and direction, review and comment on specific articles and generally act as a sounding board and a conscience for the publication.

Read MorePredictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

Read MoreRead Next

Can the Wrong ERP System Cost You Your Job?

More than one-third of all moldmaking manufacturers are custom shops, producing one-of-a-kind, unique products. Ironically, these special engineer-to-order manufacturers are the most vulnerable.

Read MoreHow to Solve Common Inventory Management Problems Related to Tooling

A practical look at what to consider when purchasing client/server inventory management software and how to implement such a program, as well as why and how it can benefit mold manufacturing operations.

Read More

.jpg;maxWidth=300;quality=90)