Engineer

AI-Powered Automation Decreases Machine Tool Programming Time

Hexagon Manufacturing Intelligence division highlights its automated computer-aided manufacturing (CAM) programming tool called ProPlanAI, that cuts the time to program factory machine tools by 75%.

Read MoreThree Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

Read MoreMaximizing Machine Tool Potential With CAM Software

Identifying specific areas where CAM software can utilize machine capabilities to benefit the user and maximize milling machine potential.

Read MoreStrategic Mold Cooling: Optimizing Molding Quality and Cycle Efficiency

Proper cooling is crucial in molding, yet often overlooked. Discover proper cooling methods to prevent defects and improve efficiency.

Read MoreUnderstanding the Elusive Nature of Mold Ventilation

A personal journey of lessons learned about the challenges of poorly designed, understood and executed mold venting.

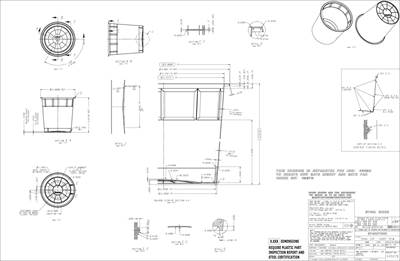

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

WatchHow to Fix Predicted Warpage Before It Happens with Windage and CAD Model Morphing

Applying windage and model-morphing techniques saved toolmaker/molder Sturgis Molded Products the time, cost, headaches of multiple part/mold design iteration loops, cumbersome cooling fixtures, and long molding cycles.

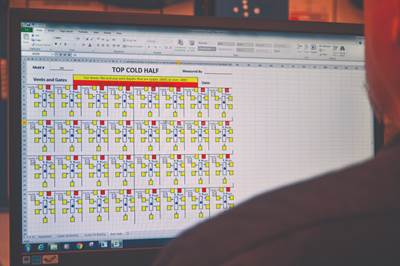

Read MoreMMT Chats: Solving Schedule and Capacity Challenges With ERP

For this MMT Chat, my guests hail from Omega Tool of Menomonee Falls, Wisconsin, who share their journey with using enterprise resource planning (ERP)—and their people—to solve their schedule and capacity load monitoring challenges.

WatchHow to Use Scientific Maintenance for More Accurate Mold and Part Troubleshooting

Discover how adopting scientific maintenance approaches helps improve mold lifespan, minimize failures, and optimize production outcomes.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read More

.jpg;maxWidth=300;quality=90)