Engineer

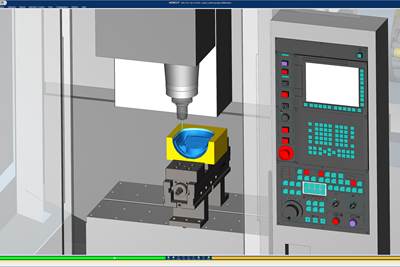

Cloud-Enabled Software Promotes Mold Strategy Improvements

IMTS 2024: Autodesk’s Fusion software suite is bigger, better and packed with more than 1,500 improvements for three- and five-axis CAM programming of molds.

Read MoreTechnology Review and Sourcing Guide 2024: Software

A variety of software technologies are utilized to create an optimized mold, from engineering services, to data management and even robotics. Access this exclusive, online-only content, including a suppliers list and software services within the moldmaking industry.

Read MoreCAD/CAM Software Update Further Streamlines Moldmaking Efficiencies

IMTS 2024: CAM-Tool V20 is presented by CGS North America, combining efficiency, precision and advanced AI capabilities to better tailor to specific mold builder needs.

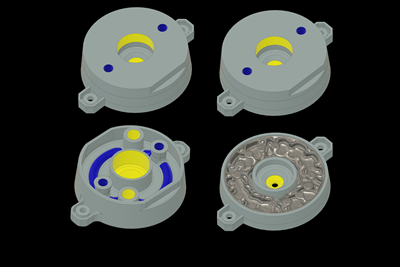

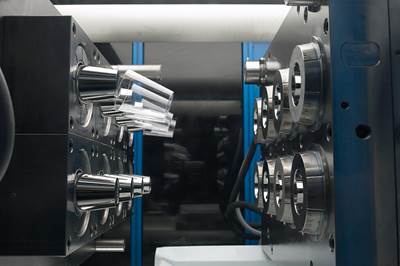

Read MoreHow to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreHow a Small Programming Change Cuts Cycle Time in Half

Overriding the CAM system when milling a series of lifter pockets helps to improve metal removal rate and increase feed rates.

Read More2024 Software Suite Update Optimizes Tool Paths, Machining Capabilities

Open Mind brings updates to hyperMILL, with enhanced core toolpath strategies as well as new functionality for increased NC programming efficiency.

Read MoreUniversal Metrology Platform Enables Moldmakers to Scale Up 3D Measurement Data

InnovMetric launches PolyWorks 2024, an open digital ecosystem that enables manufacturers to operate and manage 3D measurement data in a way that accelerates product design, development and validation.

Read MoreHow to Use a Disciplined Approach to Mold Simulation from the Plastics Point of View

What follows is a Q&A with Adam Narkter, MMT EAB member and Diversified Technologies International (DTI) business development manager.

Read MoreHow to Make Data Work for Mold Productivity and Performance

The use of digital workflows improves the impact of mold design libraries, conformal cooling and machine learning.

Read MoreDeliberate Mismatches for Easier Mold Manufacture and Improved Part Appearance

Basic principles for applying deliberate mismatch in the area between the core and cavity and between two matching plastic parts.

Read More

.jpg;maxWidth=970;quality=90)