Build

High-Precision Touch Probe for Grinders/Lathes Enables High-Accuracy Molds, Components

Increasing probing speeds and low probing force make the highly accurate TS 750 touch probe from Heidenhain reliable for even soft and delicate workpieces.

Read MoreHigh-Conductivity Core Pins

Regal BFP type high-conductivity core pins are made from C-18000 beryllium-free copper and promise resistance to wear, abrasion and thermal stress.

Read MoreHydraulic Vise Acts With High Holding Forces and Quick Clamping

The 130-millimeter double-acting vise improves speed and minimizes travel while clamping, says Jergens. It is offered with multiple mounting patterns and jaw patterns.

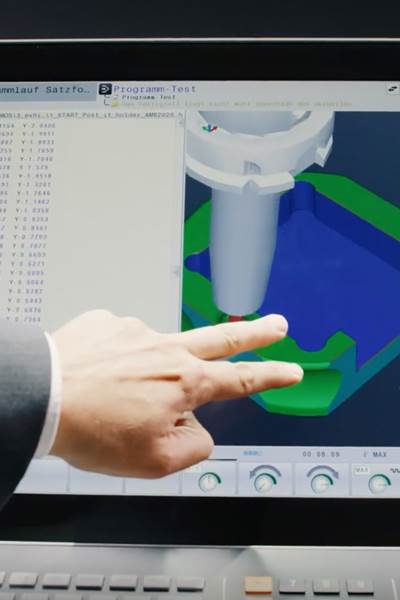

Read MoreSix CNC Control Features for Moldmakers

A CNC control should have features to automatically smooth the axis movements or allow the operator to set tolerance limits manually.

WatchMulti-Purpose End Mills Are Effective Across Multiple Job Shop Applications

Emuge-Franken USA’s comprehensive Top-Cut VAR end mill line cuts virtually all materials, expanding high performance, durability and long tool life.

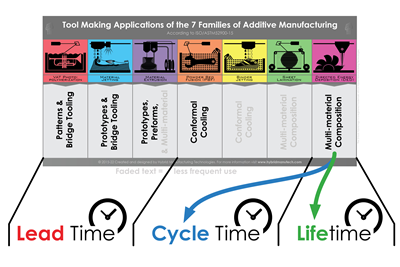

Read MoreThe Mold Builder’s Guide to Additive Manufacturing

An overview of mold building needs that AM can address and specific AM techniques best suited to each.

Read MoreMagnetic Ring Encoder Delivers Functional Safety for Machine Tool

Heidenhain’s contamination-resistant, absolute modular magnetic angle ECM 2400 is suitable for high rotational speeds, angular accelerations and limited space.

Read MoreDesktop Metal Qualifies D2 Tool Steel for Additive Manufacturing

The company says its Production System binder jetting technology enables production of cold work tool and die parts with high hardness, wear resistance and compressive strength.

Read MoreEnhanced Remote Monitoring, Data Evaluation Platform Boosts Manufacturing Efficiency

Per machine tool user requests, the new features identified in Heidenhain’s StateMonitor version 1.4.0 better connect machine tool date digitally, improve production efficiencies and introduce maintenance support.

Read MoreLatch Locking Units for Precise Control of Parting Planes

Hasco’s new latch locking units feature double-sided action and DLC-coated functional surfaces.

Read More