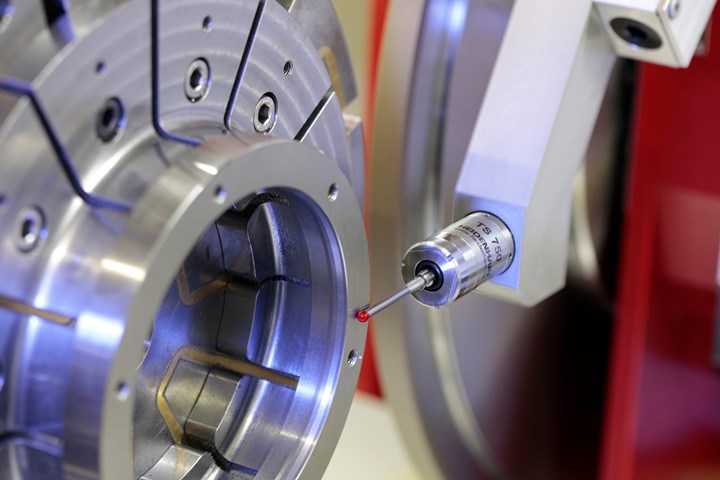

High-Precision Touch Probe for Grinders/Lathes Enables High-Accuracy Molds, Components

Increasing probing speeds and low probing force make the highly accurate TS 750 touch probe from Heidenhain reliable for even soft and delicate workpieces.

Photo Credit: Heidenhain

Heidenhain’s TS 750 high-precision touch probe is now available for in-process workpiece measurement in grinding machines and lathes. The highly durable probe offers the ability to state the reproducibility of its jobs at increased probing speeds with low probing force, the latter of which Heidenhain says is an important benefit when working with soft or delicate workpieces. Ultimately, when dialing into mold applications, the machine is a solution for high-accuracy parts grinding.

The TS 750 operates with high-precision pressure sensors, with force analysis for generating the trigger pulse. The forces that arise during probing are processed electronically. This method is said to deliver extremely homogeneous, 360º probing accuracy. It offers high probing speed of up to 1 m/min and does not require a minimum speed.

In addition, due to its low probing forces of approximately 1.5 N (axial) and 0.2 N (radial), the TS 750 can attain high probing accuracy (±1 µm) and repeatability with almost no effect on the measured object. Only on further deflection do the forces of the springs take effect until the machine stops.

The probe also delivers reliable measurements after prolonged use; even after five million probing cycles, Heidenhain contends, the TS 750 touch probe is still highly accurate, offering a probing repeatability of down to 2 standard deviation ≤0.25 µm at its high probing speed.

Related Content

-

The Secrets to Hard Milling Success

The Secrets to Hard Milling Success

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

-

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.