Hydraulic Vise Acts With High Holding Forces and Quick Clamping

The 130-millimeter double-acting vise improves speed and minimizes travel while clamping, says Jergens. It is offered with multiple mounting patterns and jaw patterns.

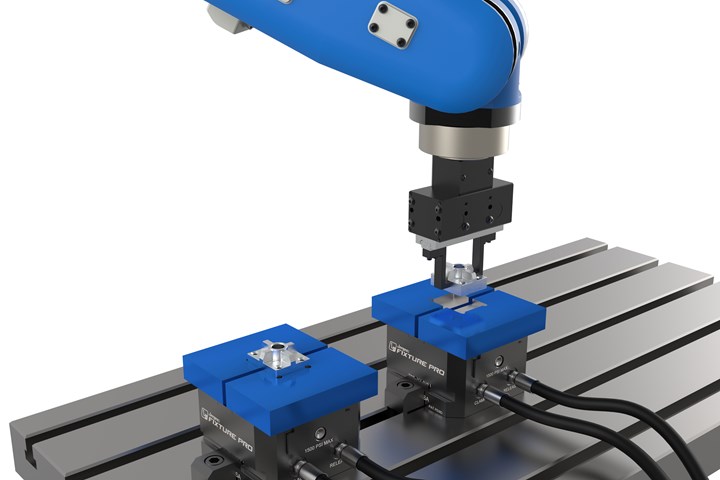

Jergens’ 130-mm double-acting hydraulic vise is shown here in an automated application. Photo Credit: Jergens Inc.

Jergens Inc. highlights its new 130-mm double-acting hydraulic vise with high holding forces, quick clamping and repeatability for improved speed and part tolerance. The vise comes standard with multiple mounting patterns, different jaw options and easy access to plumbing and maintenance ports.

Jergens’ hydraulic vise offers users the ability to position the jaws just outside of the dimension of the workpiece to minimize travel when clamping. This, in combination with the speed of hydraulic workholding, reduces clamping and unclamping operations to about one second. Ease of use for users translates to repeatable operations, and increased machine uptime and productivity increases, especially for high-mix, low-volume manufacturers.

The vise features a steel body and internal hardened (low-friction process) components for greater performance and enhanced durability, even in harsh environments. Only low operating pressures are needed, allowing the vise to perform well directly off of machine hydraulics. For flexibility, both Fixture Pro QLS and industry-standard 96-mm Quick-Loc mounting patterns are included in every vise. According to Jergens, the 130-mm vise is versatile and well-suited for multiple CNC machining applications including vertical, horizontal, rotary, five-axisa and robotic setups.

Quick-change soft jaw sets, available in high-strength aluminum (blue anodize finish) or low carbon steel (black oxide finish), extend the range of holding options. Case-hardened jaw inserts are also part of the offering and provide extra secure holding making them well suited for first-pass operations in raw materials.

For a complete solution, Jergens also offers hydraulic pump kits for powering the 130-mm hydraulic vise. Kits come with everything required to hook up and control a vise including the compact pump—mounted horizontally or vertically—and a manual or solenoid zero-leak valve to control the clamping action. Clamping force can be adjusted with the filter/regulator, also included. These kits are designed for powering single vise setups, however, multiple vise applications are also possible.

Related Content

-

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

-

Tips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

-

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

.jpg;maxWidth=300;quality=90)