Build

MMT Chats: Wepco's Journey with Metal 3D Printing

MMT's Editorial Director, Christina Fuges sits down with Wepco's director of manufacturing Support, Amanda Wiriya to talk about Wepco's journey with 3D printing and how the company brings awareness to the community about the growing moldmaking industry. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Watch2022 Sourcing & Technology Guide: Mold Materials

Proper selection of the appropriate mold material is critical to manufacturing a high-quality mold. Tool steel, aluminum, copper and alloys are some of the materials used.

Read MoreCoarse Pitch Cutter Additions Retain High Tool Rigidity

Tungaloy’s TungForce-Rec series to be showcased at IMTS 2022 now offers eight new coarse pitch cutters to its square should milling line to meet demanding application needs.

Read MoreEvaluating Metal Powders for Conformally Cooled Mold Inserts

Mechanical properties and design software techniques reveal the benefits of a modified high thermal conductivity metal powder for 3D printing in moldmaking.

Read MoreHigh-Speed VMC Offers More Intuitive Machining, Surfacing

In addition to inherent five-axis benefits, the Genmill VFM-2416 five-axis from Expand Machinery, debuted at IMTS 2022, offers a range of features for optimal surface finishing.

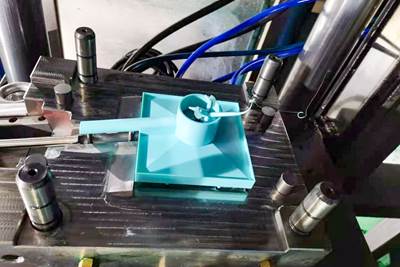

Read MoreVIDEO: How a Mold System Reduces Processing Costs and Cycle Time

In this digital demo, Canon Virginia demonstrates how their shuttle mold system can run two parts at once, reducing processing costs and cycle time.

WatchThree Advances in Vision Measuring Technology for Moldmaking

Next-generation metrology solutions are streamlining shopfloor automation and quality control for mold builders.

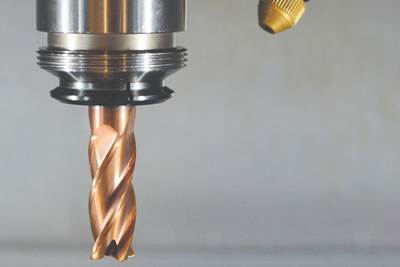

Read More2022 Sourcing & Technology Guide: Cutting Tools

Cutting tools are used on machine tools to cut metal, and are one component of the overall mold machining process to consider when looking to improve speeds, feeds, wear and surface finish.

Read MoreFlexible Five-Axis Machine Ideal for Lights-Out Manufacturing

At IMTS 2022, Kitamura Machinery is revealing its all new MedCenter5AX simultaneous five-axis machining center with high precision and rigidity, enabling an automated production process.

Read More2022 Sourcing & Technology Guide: Machining

Machining (via the machine tool and cutting tool) shapes metal workpieces. Understanding both traditional and advanced machining techniques is critical to overcoming the various dimensional and finish challenges.

Read More