Build

Vertical Machining Center Connects the User to the Control

Powered by a Siemens Sinumerik One control, TRAK VMCsi machine at IMTS 2022 attains fast feeds, optimized part finishes and higher productivity for the everyday mold builder.

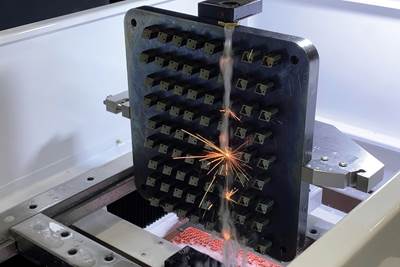

Read More2022 Sourcing & Technology Guide: EDM

EDM refers to wire, sinker and small-hole electrical discharge machining. Components include drives, generators, programming, flushing, wires, electrodes, graphite, filters and fluids.

Read More2022 Sourcing & Technology Guide: Additive Manufacturing

3D printing, or additive manufacturing, simplifies the moldmaking process by making mold inserts, mold components, end-use parts and ancillary equipment.

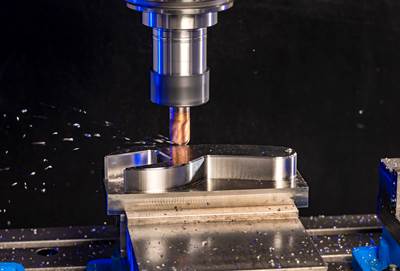

Read MoreBall-End Tool Contours, Chamfers and Finishes in One Pass for Most Materials

The new IMCO Carbide Tool Pow•R•Arc end mill, to be shown at IMTS 2022, emphasizes speed for moldmakers. The cutter is able to run and increase feed rates to machine one’s mold up to five times faster than a four-flute tool.

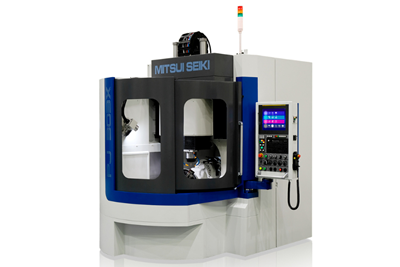

WatchFive-Axis Machining Center Accommodates Small Workpieces

Mitsui Seiki’s compact PJ 303X machining center, to be highlighted at IMTS 2022, provides high precision, speed and versatility for critical parts like lens molds, medical products and EDM electrodes.

Read More2022 Sourcing & Technology Guide: Mold Components

Mold components make the mold work and the mechanisms used to deliver a quality end product. Key components include mold bases, pins, ejectors, lifters, bushings, guides and alignment devices.

Read MoreVIDEO: How to Change Out Molds in 10 Minutes or Less

Is a 10-minute mold change possible? Check out this demo to see how it can be done.

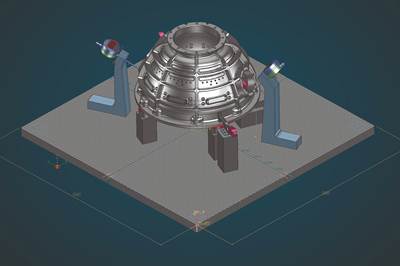

WatchParametric Design Software Drives Mold Manufacturing Automation and Efficiency

Tebis America’s third release of Tebis 4.1 features new interactive features for the everyday mold builder at IMTS 2022, including complete collision control and faster programming.

Read MoreFrom Injection Mold Venting to Runnerless Micro Molds: MMT's Top-Viewed June Content

The MoldMaking Technology team has compiled a list of the top-viewed June content based on analytics. This month, we covered an array of topics including injection mold venting, business strategies and runnerless micro molds. Take a look at what you might have missed!

Read MoreMetric-Diamond-Coated End Mills for Graphite Electrode Machining

As the industry continues to adopt graphite electrodes, Crystallume introduces its high-precision, tight-tolerance coated end mills to meet moldmaking needs.

Read More