Build

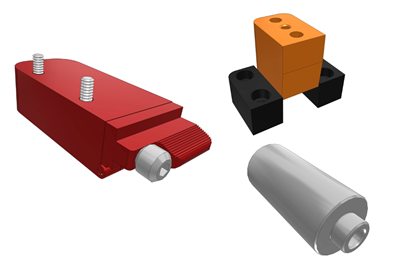

Double Rack Lifter Expansion Enhances Undercut Release Capabilities

CUMSA’s KR lifters, like the DR or XR series, are designed to reduce the size of the overall mold and simplify tool construction. New KR series sizes improves coolant delivery and mold undercuts.

Read MoreGantry Machines Meet Industry-Specific Requirements for Mold and Die Makers

Zimmerman is putting on a virtual display of its highly rigid and efficient FZ42, FZ37 and FZ32 machines at IMTS 2022.

Read MoreHot Edge Gate Nozzles Create Clean Gate Vestiges, Reduces Tip Wear

Power Point Hot Edge Gate Nozzles from Melt Design Inc. enable hot runner systems to run long periods of time without failure or maintenance.

Read MoreReimagining Moldmaking with Technology

A look at some of the technology mold builders have expressed a growing interest in and are now actively investigating, including advancements in mold design, 3D printing, automation, machining, inspection and repair.

Read MoreFully Automatic Boring Head Performs Closed-Loop Boring Operations

The Big Kaiser EWA Automatic Fine Boring System from Big Daishowa offers three configurations — full integration, PC or tablet control — to eliminate scrap, inaccuracy and cost. See the machine at IMTS 2022.

Read MoreLarge Surface Grinders Are 20% More Efficient

New FSG-2048ADIV and FSG-2064ADIV machines from Chevalier Machinery offer several design features to mold builders to shorten processing and non-processing preparation while delivering high-precision workpieces.

Read MoreLinear AMS Merges With Shapeways

The merger is said to enable both companies to better serve their customers’ needs — such as Linear AMS’ competencies in plastics mold tooling and production — while accelerating innovation in additive manufacturing.

Read MoreIntegrated Manufacturing System Showcases Smart Automation for Mold Builders

Whether mold builders are sourcing their cutting tools from an external manufacturer or looking to bring this function in-house, ANCA’s AIMS system offers a flexible, scalable ecosystem for factory connectivity.

Read MoreExpansion of Online Moldmaking Catalog Streamlines Mold Component Search and Sourcing

DMS Components has launched a new part number lookup feature and 3D PDF facesheets to improve the online experience for design engineers and purchasing departments when searching for mold components.

WatchVIDEO: Complex Valve-Gate Hot Runner Molds and Processing Reinforced Material Tips

Tony Brodzeller, Technical Sales Director at Mastip talks about its complex 72-drop valve-gate stack mold hot runner system, tips for processing reinforced materials and his perspective on the future of moldmaking.

Watch