Reimagining Moldmaking with Technology

A look at some of the technology mold builders have expressed a growing interest in and are now actively investigating, including advancements in mold design, 3D printing, automation, machining, inspection and repair.

Moldmaking is thriving, according to MoldMaking Technology readers. Whether it is a result of the changing role of the mold builder, global manufacturing strategies, key end market trends, increased demand for plastic parts and packaging or re-shored projects due to supply chain issues, the moldmaking industry is busy. Many are building more molds this year and are running more machine hours.

New business opportunities are also impacting business levels. Mold builders are learning to pivot to take advantage of the changes taking place across different end markets, like the electrification of automobiles, miniaturization, in-mold assembly and more. Some are keeping on top of emerging technologies such as 5G, Intenet of Things (IoT), autonomous vehicles, AR/VR and consumer robotics to see where their capabilities fit, and others are considering specialization such as liquid silicon rubber molds and other nontraditional markets.

Moldmaking is also evolving — into mold manufacturing. The difference is that the former is a task and the latter requires systems, processes and specialized skills. This facet of manufacturing has distinct challenges and complexities because a mold is an integrated machine in a process built upon data. Today, moldmaking has moved beyond an art and craft to a science with technology advancements aimed at engineering and building a better, more cost-effective mold.

Now Is the Time to Reimagine Moldmaking

Mold builders are looking at their operation and reimagining what it can be by employing new technology and workforce solutions — for example, advanced manufacturing technology, material innovation, smart molds with machine learning and artificial intelligence, and innovative workforce development, education and training initiatives.

Keeping pace with this increased business and evolution takes the right technology and processes, so mold builders continue to invest. Many are buying more tool steel and plan to purchase machine tools. They also recognize the power of partnerships in developing technology to improve mold-building efficiency.

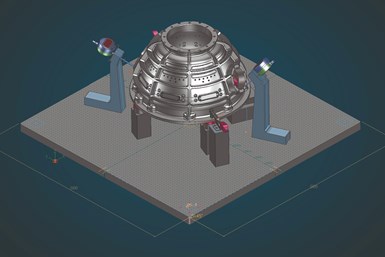

Some of the technology mold builders have expressed a growing interest in and are now actively investigating include advancements in mold design, 3D printing, automation, machining, inspection and repair.

Mold Design and Engineering – Mold builders are evaluating their current

Parametric design software drives mold manufacturing automation and efficiency. Photo Credit: Tebis

work process and employing design optimization and collaboration tools to reduce iteration time, improve part and mold design and reduce lead times. Some recent solutions include parametric design software that offers automation and efficiency via collision control and faster programming, reduced manual CAM programming and automatic job sequence calculation; fully integrated CAD/CAM; CAM finishing strategies for new cutting tool shapes; predictable mold machining using lasers, macros, automation, specific CAM software and algorithms; improved CAD-to-CAM workflow; surface-based CAM systems for high-accuracy 3D machining and CAD, CAM and additive manufacturing (AM) tools in the same software package and user interface to ease programming.

Hybrid metal 3D printing redefines mold component production. Photo Credit: Matsuura Machinery USA

3D Printing – The number of technology suppliers focused on moldmaking applications for their 3D printing solutions has increased over the past few years, with many partnering with mold builders to develop and prove their technology. Some advancements include 3D printing complex injection molds, inserts and components while fast-tracking mold designs and validations; limitless options for cooling a mold's difficult-to-cool areas; software for intelligent conformal cooling channel design for faster cycle times and 3D-printed mold sensors to reduce cycle time via increased heat dissipation.

Machining – From simulation and control technology to five-axis machining and deep-hole drilling, there are plenty of options for today's mold manufacturers to up their game, including CNC simulation software that incorporates data from the machine, cutting tools and stock material; simulation software that limits tool deflection for better mold surface finishes; CNC controllers with fully integrated process monitoring; machine optimization control technology that reduces CAM processing time and minimizes multiple setups; hard milling accuracy and repeatability centered around predictable manufacturing; heavy-duty, precise five-axis machining with scheduling software; enhanced grinding flexibility for grinding varied materials and large molds, as well as extreme depth-to-diameter hole drilling technologies that can create holes with high precision.

EDM – Moldmakers continue to rely on EDM routinely, so staying on top of EDM trends is essential. For example, upgraded EDM controllers for improved efficiency and scalable flexibility, wire EDMs with high precision, intelligent interfaces and sinker EDM with a programmable work tank level for ergonomic loading and unloading that also maximizes unattended job operations with different oil level requirements.

Cutting Tools – Mold builders are always seeking better cutting tool

Geometry inserts target difficult-to-machine materials used in moldmaking. Photo Credit: Allied Machine & Engineering

performance, faster metal-removal rates and reduced finishing cycle times to increase throughput. A few key developments include shrinking, balancing, presetting machines, tool holders, cutting tools and 3D sensors that use Industry 4.0 principles to increase productivity; geometry inserts for difficult-to-machine materials; barrel-shaped cutting tools to reduce finish and semi-finish machining time of complex surfaces and modular milling systems.

Data Management – The industry has seen an increased demand for digitization and better data handling across the enterprise and supply chain. For example, digitizing moldmaking with OEE tracking, improved ERP systems to collect, analyze and use data and machine monitoring.

Automation – Mold builders are increasing automation throughout the shop with semi- and full-automation solutions that improve utilization, run lights-out operations, improve profitability and performance and increase output and flexibility. A few key areas are feature-, attribute- and script-based CAD/CAM automation, digitalization of manual processes, quality process management software, palletization with electrode milling, EDM and five-axis machining, robots and robotic cells.

This probing line comes with multichannel radio transmission for highly accurate mold measurements. Photo Credit: Marposs

Inspection and Measurement – Producing the highest quality molds requires high-quality control practices, which are dependent upon accurate, reliable measurements. Mold builders can take advantage of several metrology advances to tackle today's inspection and measurement challenges, including entry-level, compact CT scanning systems for non-destructive mold inspection, probes designed for high-accuracy five-axis machining centers and milling machines; on-machine verification, measurement and intelligent modification technology; and artificial intelligence-inspired inspection and defect detection.

Maintenance and Repair – Many mold builders are experiencing an increase in mold maintenance, repair and re-engineering opportunities due to reshoring and these jobs require specific products, equipment and skills. A few new product developments that ease in-house mold maintenance and repair include laser welder generator technology, high-efficiency fiber optics, pulse-shape settings and articulating arms, as well as ultrasonic cleaning systems that help reduce manual labor costs associated with mold maintenance.

Last but not least, we can’t avoid discussing the people side of mold

Mold manufacturers can take their mold machining to the next level with developments in machine tool controls, simulation, five-axis machining, hard milling, deep-hole drilling and grinding. Photo Credit: Getty Images

manufacturing, too, because the technology a shop invests in will dictate the skill level employees need. This means training your team to ensure they can run the equipment, leverage the technology and streamline operations to avoid mistakes and errors, leading to a better, more cost-effective mold.

The International Manufacturing Technology Show runs September 12 - 17, 2022 at McCormick Place in Chicago. Register for IMTS today to start planning your show.

Related Content

Achieving Flexible Capacity with Automation

This high-mix, low-volume manufacturer embarked on a year and a half program to introduce robotics to its manufacturing process.

Read MoreMold Builder Meets Increased Domestic Demand With Automated Cells

Burteck LLC experienced significant demand increases due to reshoring and invested in automated machining cells to step up its production output quickly and avoid losing business.

Read MoreQuality Tool & Die Enhances Performance With Advanced EDM and Milling Technologies

The adoption of Mitsubishi wire and sinker EDMs, along with the OPS Ingersoll five-axis milling machine with automated cells, has enabled unmanned operations and improved precision. As a result, QTD has expanded its facility, grown its workforce and increased its business by 10-15% annually.

Read MoreMachine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More