Build

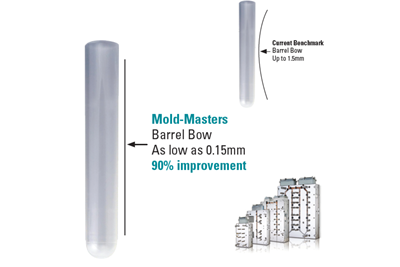

Minimization of Core Shift Enhances Part Quality

The Mold-Master Symfill technology allows the melt to enter the nozzle runner channel from multiple sides, which has been proven to reduce barrel bow by up to 90%.

Read MoreVIDEO: Taking a People Before Product Approach to Growing a Business

Angela Elsey, President of PCS Company, shares her journey into moldmaking, perspective on the industry and plans for the business.

WatchEntry-Level Cylindrical Grinding Machine

The Studer S100 is suitable for grinding geometrically defined basic forms and contours for a wide range of parts, all of which can be generated with the machine’s interpolating axes.

Read More5 Sinker EDM Advancements

Speed, machine design, software, artificial intelligence and automation help maximize sinker EDM productivity.

Read MoreQuick Action Sliding Locks Improve Workholding Setup Time, Reliability

Fixtureworks brings shops a variety of adjustable sliding lock configurations and clamps for those applications where disassembly and changeovers are frequent.

Read MoreAll-Round Cutter with Center Cutting Capability Provides Mold Machining Versatility

Tungaloy expands the DoMultiRec multifunctional milling/drilling tool line to better take on multiple machining operations.

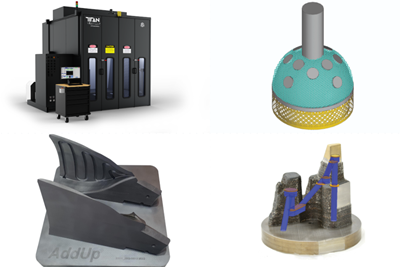

Read MoreA 3D Printing Retrospective

A personal review of the evolution of 3D printing in moldmaking throughout the past 25 years.

Read MoreHigh-Precision Shaping Program Further Automates Precision Moldmaking

Mantle expands the capabilities of its hybrid metal 3D printing technology, enabling finer feature creation and expanding the geometries compatible with its TrueShape process.

Read MoreExpanded Drill System With Drill Sleeves

Tungaloy adds drill sleeves to the standard lineup, enhancing drilling productivity of Swiss-type sliding-head automatic lathes, as well as 48 new drill heads, to address precision, productivity and more extensive hole size requirements.

Read More3D Printing Technologies for Moldmaking Applications

3D printing technologies, from conformal cooling to complex mold building, are making an impact on the moldmaking industry, one innovation at a time.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)