Build

New Michigan Technical Center for YCM Alliance

YCM Alliance held a grand opening of its new Technical Center in Sterling Heights, Michigan, last week, which is the first in a series of centers designed to showcase and demo machining solutions for die and mold machining, ultra-high-speed machining and general parts machining.

Read MoreShaping Steel Enables More Complex, Efficient Injection Molds

AddUp’s AISI 420 stainless steel is commonly used to manufacture molds for plastic injection molding, as it has high mechanical strength and good corrosion resistance.

Read MoreTreatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read MoreSLM 3D Printer Focuses on Complex Geometry Development

Newly launched DMG MORI Lasertec 30 SLM US 3D printer features adaptive beam control, noncontact recoating and a hybrid toolpath strategy for more dynamic additive capabilities.

Read MoreMold Care, 3D Scanner Best Practices, the State of Maintenance & More Most-Viewed April Content

April held a little bit of everything for MoldMaking Technology. From mold care and maintenance to 3D scanner and printing best practices, take a look at what might have missed your radar.

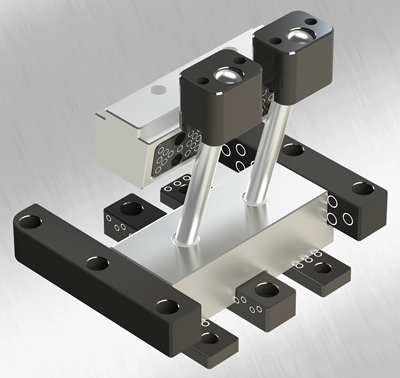

Read MoreEnlarged Ejector Range to Cover Moldmaking Applications

Hasco says the approximately 600 additional new versions gives its ejector portfolio maximum demolding flexibility.

Read MoreMantle Wins SME Additive Manufacturing Start-Up Technology Award

The metal 3D printing company’s TrueShape technology for precision moldmaking was recognized at RAPID + TCT conference for its feasibility, market potential and uniqueness.

Read MoreSlide Components Can Run Greaseless, Provide New Side Actions

Progressive Components says the Z-Series proprietary treatment guarantees long-term operation and durability, while there are also new side-action options for greaseless applications.

Read MoreWire-Laser Metal 3D Printer for Efficient, Versatile Processing

The MC Machinery Systems printer applications include rapid prototyping, mold and die, one-offs, short runs, mass manufacturing, maintenance, repair, tooling and more.

Read MoreWire EDM Series Designed for Ease of Use, Flexibility

GF Machining launches the first model of its new Cut F Series, featuring additional machining enhancements and functions to automatically identify and adapt wire speed during the wire EDM process.

Read More

.jpg;maxWidth=300;quality=90)