Basics

The Basics of High-Speed EDM Hole Drilling

This article discusses how EDM hold drilling - designed for fast, accurate small- and deep-hole drilling applications - has become a whole new method of manufacturing molds and parts.

Read MoreHow to Choose a Machining Service Provider

Rather than drive your business into the ground by trying to purchase extra equipment, get help and outsource to a shop that specializes in each specific machining method.

Read MoreFor the Business-side of Moldmaking Try A Consultant

Let experience, education and references be your guide to choosing the best consultant.

Read MoreWhat Do YOU Know About Mold Steel Quality?

Problems associated with the texturing or polishability of a mold cavity can often be traced back to the mold steelmaking process.

Read MoreISO 9000 - Pt.15 Handling / Storage / Packaging / Preservation / Delivery

A Series of International Standards for Quality Management and Quality Assurance. This Clause is designed to provide a method to prevent damage or deterioration (i.e., preserving and segregating product).

Read MorePlating Tips for Better Productivity

The true differences between types of plating and why one may be better than another for efficient, quality production.

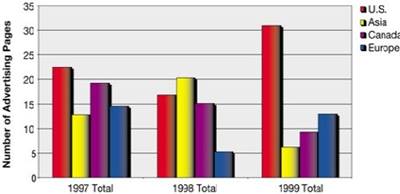

Read MoreGrowth Strategies for the U.S. Moldmaker - Understanding Your Competition - Here and Abroad

This article begins a four part series that will describe the current competitive conditions in the plastics tooling industry and what some companies are doing to grow their businesses amidst challenging conditions.

Read MoreHow to Prevent Hot Runner Leaks

One of the most common concerns expressed by molders about hot runner molds is the threat of a leak of molten plastic causing the manifold pocket to fill.

Read MoreA Workforce Development Solution: The SPI Apprentice Training Grant Program

One of the biggest problems facing the plastics industry today is the shortage of qualified labor

Read MorePlanning to Purchase a Hot Runner System? What You Need to Know Before You Get Those Quotes

While they are certainly not a necessity in the moldmaking industry, more and more molders are discovering the numerous benefits hot runner systems offer the molding process: faster cycle times, no waste in the sprue and runner system and elimination of additional operations such as grinding the scrap material.

Read More