Auxiliary Equipment

Moulding Expo 2017: More Than Just Hammers, Pliers and Saws

The International Trade Fair for Tool, Pattern and Moldmaking opens its doors today.

Read MoreSLIDESHOW: Technology Showcase, Amerimold Product Showcase

This is our industry’s show, and this week we bring you yet more previews of what you can expect to find as you walk the aisles of the biggest Amerimold Expo yet.

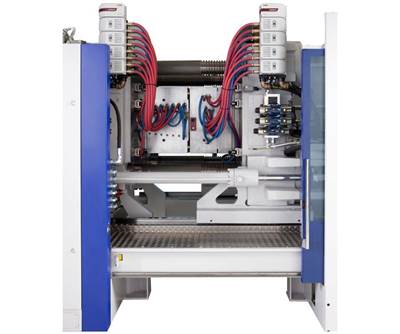

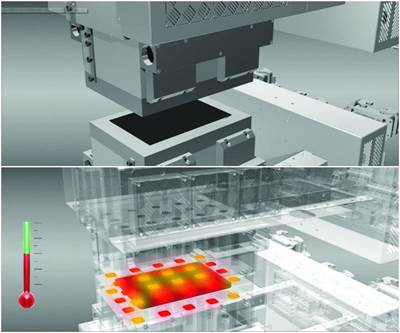

Read MoreAdvanced Thermal Control

Integrating heating and cooling into the mold helps improve injection-molding control and flexibility.

Read MoreSLIDESHOW: Technology Showcase, After K

By all accounts K 2016 was a success. According to show management, attendees were delighted with the wealth of new technical developments presented by raw materials producers, machinery manufacturers and producers of semi-finished and technical parts. Here are some technology highlights.

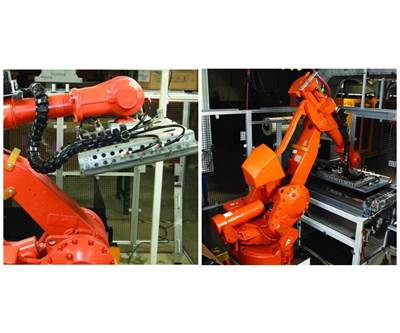

Read MoreIncorporating Robotics

Consider robots in part and mold design, and molding processes to increase part quality and meet growing customer demands.

Read MoreA Hi-Tech Molding Machine in Action

Check out this video taken during the official opening of Hi-Tech Mold and Engineering's new Technology Center. It shows a fully automated Engel duo 3500-ton "smart" molding machine demoing (dry) a Hi-Tech mold for an interior automotive part.

WatchAmerimold is for... Achievers!

Following up on my blog from last week about our Amerimold Expo, which will be held June 15-16 in Novi, Michigan, I thought I’d call out some aspects of the event that will surely be of interest to our moldmaking audience. Why? Because moldmakers are achievers.

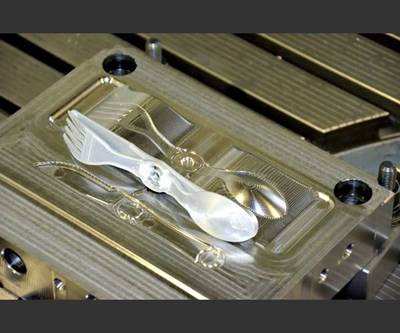

Read MoreA Mold Shop OEM

Years of helping customers save time and money in liquid silicone rubber (LSR)—a material that involves very different considerations from plastics—has led this shop to develop its own product line.

Read MorePreparing for Takeover Tooling

With the right preparation, moldmakers can insulate themselves from takeover tooling crises and add greater value to the molder.

Read MoreConsiderations for Assessing Robotics Requirements

Knowledge of part de-molding, end-of-arm tooling construction, part defects caused by the mold-robot interface and available automation options is key for suppliers looking to add greater value.

Watch