Automation

Streamlining Your Setup Operations with the Right Workholding System

Creating a powerful manufacturing cell from a one-minute palletization solution.

Read MoreMachining Madness

IMTS is a time to both discover ways to make your existing equipment more efficient and to discover the new machine tool technologies available.

Read MoreUnscrewing Core Design Provides Fast, Accurate Core Positioning

Although PERC (Programmable Electric Rotating Cores System) is not a brand-new technology, it warrants a second look as a way for moldmakers to provide another value-added service to their customers.

Read MoreMold Builders Carve Lean Niche

Commodity-oriented consumer manufacturing left North America, but mold industry survivors are finding strong growth in technical market sectors.

Read MoreMolding Success Through Automation

HSM technology helps U.S. moldmaker maintain world-class productivity and business growth.

Read MoreDoubling and Quadrupling Machining Speed, Capacity and Output

Vertical machining centers help to achieve the rapid tool production time a medical thermoformer’s customers demand.

Read MoreInvestments in Productivity: Automation Integration In the Toolroom

By integrating machining, workpiece and cutting tool management, CMM verification, and a Web-based video and control system, a completely integrated cell producing fully qualified electrodes through automated manufacturing can be created.

Read MoreHow to Achieve Tool Shop Optimization

A five-step methodology to face your delivery, quality and cost challenges head on.

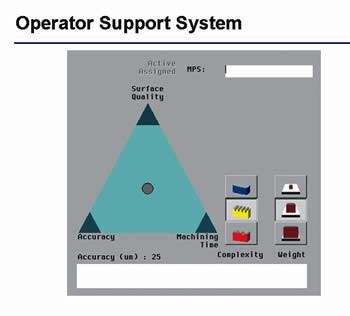

Read MoreSmart Machining: A New Development in High-Speed Machining

Improved process reliability, optimized machining performance and reliable unmanned operation are the results of smart machining implementation.

Read MoreAutomation

EROWA Technology (Arlington Heights, IL) will highlight its many automation solutions.

Read More

.jpg;maxWidth=300;quality=90)