Machining Madness

IMTS is a time to both discover ways to make your existing equipment more efficient and to discover the new machine tool technologies available.

IMTS is a time to both discover ways to make your existing equipment more efficient and to discover the new machine tool technologies available. This year promises to bring higher quality products reflective of the shrinking concern over price and the stronger focus on performance as the deciding factor when making purchasing decisions.

On the exhibit floor at this year’s IMTS look for a focus on end use markets to help keep manufacturers competitive within their individual market segments. A seeming trend will be booth displays designed and laid out according to specific applications—key markets such as medical, aerospace and mold/die. This arrangement will help you save time during your visit by allowing you to focus on your own shop’s challenges via the booth “areas” that apply to you.

In that regard, we have narrowed our focus a bit to provide those of you manufacturing molds for the packaging industry with a guide to the moldmaking applications, technologies and strategies specific to the packaging market segment (Packaging Molds Go High-Tech to Improve Productivity and Economy). Look for remaining industry focus features in October and December with features on electronics and aerospace/defense, respectively.

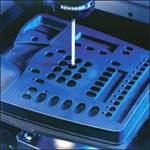

Some of the technology you will see during IMTS includes machining strategies and machine tool development centered around maximizing efficiency and flexibility for the moldmaker; new EDM and HSM technology; multi-axis machining; high-speed, hard milling; micro-machining; side-by-side machining; parallel machining; five-axis gun drilling; zero/negative stock machining; high-feed milling; five-axis machining; high-speed programming, tooling and machining techniques; machines with the strength, rigidity and reliability to handle complex contours and fine surface finishes at high speeds; advanced CNCs providing major gains in servo performance to raise feedrates and shorten cycle times; spindles that are refined, with rpms pushed to new limits; and, improved cutting tools delivering higher feedrates and longer cutting life.

You also will encounter cutters and tooling that increase speed and completion of machining operations; specific cutting edge geometry and grade advancements; sophisticated coatings; toolholding technology that addresses vibration; sinker and wire EDM automation; filtration advancements; developments in five-axis wire EDM’ing; automation options for machine tools; and, upgraded CAM software to take advantage of the latest machine and control technology.

More than 1,200 exhibiting companies will be showcasing their products. And in this issue—we are highlighting some of the moldmaking-specific technology offerings.

To continue the IMTS theme, this issue also features articles on how to get the most from your multi-axis machines (Getting The Most from Your Multi-Axis Machines); guidelines for selecting the right tool presetting and measuring system (Toolroom Management: Presetting Increases Profits and Productivity); how to choose and size the appropriate metalworking filtration system (How to Choose and Size the Right Metalworking Filtration System ); machining trends for drilling coolant channels in mold bases (Machining Trends for Drilling Coolant Channels in Mold Bases ); how to streamline your setup operations with the proper workholding system (Streamlining Your Setup Operations with the Right Workholding System ); and, a review of the standards for machine safety (Standards for Machine Safety ).

For more information on IMTS visit www.imts.com. We hope to see you there! Stop by MoldMaking Technology’s booth, B-1001.

Related Content

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreRead Next

How to Select and Use Your Vertical Machining Center

Competitive shops need to consider the true capabilities of their VMCs to achieve a high level of accuracy and surface finish.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;maxWidth=300;quality=90)