Automation

EDM and Automation: The Present is the Future

By automating its EDM department, F&S Tool has been able to increase sales by 50 percent.

Read MoreGetting the Job Done Quicker: What You Need to Know

EDM equipment manufacturers, along with EDM experts, discuss the latest advances to achieve optimum efficiency while maintaining quality.

Read MoreSpecializing in Success

The members of MoldMaking Technology's Editorial Advisory Board express their views on the benefits of specialization to a moldmaker.

Read MoreHigh-Performance Machining - Putting It Into Practice

Most companies are looking for three basic things: to make parts faster, better and cheaper. Often, meeting these goals requires a change in process, tooling, the machine tools and/or CAM software.

Read MoreDesigning Plastic Components and Injection Molds for Robotically Dispensed Foam-in-Place Gasketing

While robotic technology improves design flexibility and productivity, up-front attention to component and mold design can lead to even higher gains

Read MoreThe EDM Forecast: Sunny Skies

Despite the growing popularity of alternative technologies, new trends in EDM automation and product efficiencies guarantee its continued use well into the new millennium.

Read MoreAutomation in Electrode Milling

Excell Machine and Tool saw significant benefits by automating its graphite machining center.

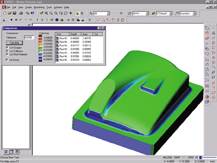

Read MoreAdvances in Automation for Mold and Die - High-Performance Machining and EDM

Recent developments in automation are providing benefits for the high-performance machining (HPM) of electrodes and steel mold components.

Read MoreAutomation of the Mold Development Process

Three dimensional-based mold design solutions allow mold tooling companies to automate mold manufacturing.

Read More

.jpg;maxWidth=300;quality=90)