Additive Manufacturing

EDM, Precision Milling, 3D Printing Improves Accuracy, Reduces Machining Time

IMTS 2024: MC Machinery Systems showcases an array of EDM and precision milling tools, as well as a wire laser metal 3D printer, all of which have the capacity to meet moldmaking needs.

Read More3D Printed Manufacturing Aids Improve Molding Efficiency

Moldmakers and molders turn to 3D printing for end-of-arm tools, fixtures for increased safety and functionality, lower cost and faster turnaround times.

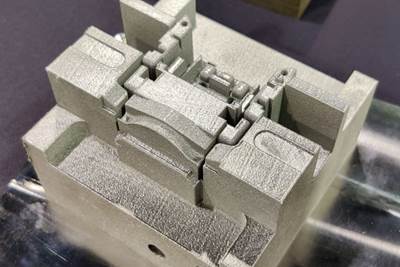

Read More3D Printing Innovates Hot Runner Manifold Design

Metal 3D printing combined with a conventionally machined manifold block overcomes flow shadows on valve gates and offers faster color changes while providing closer system pitch centerlines between cavities.

Read MoreWire-Laser Deposition Meets Automation for Standardized 3D Printing Workcell

Meltio, FANUC and Accufacture introduce Alchemist 1, a preconfigured solution highly applicable to moldmaking that is meant to expand the horizons of metal 3D printing.

Read MoreNPE 2024: Additive Manufacturing Assisting, Advancing the Plastics Industry

Exhibitors and presenters at the plastics show emphasized 3D printing as a complement and aid to more traditional production processes.

Read More8 Ways the Plastics Industry is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE 2024.

Read MoreMold Materials, 3D Printing Technologies for Next-Gen Moldmaking

As moldmaking advances, so too do the materials and processes involved in their efficient production, including these latest mold materials and 3D printing technologies.

Read MoreXact Metal, Uddeholm Partner to Offer Corrax Tool Steel Powder

Moldmakers and molders will have access to a mold steel capable of an A1 surface finish post-polishing, supporting the industry’s expansion into metal 3D printing.

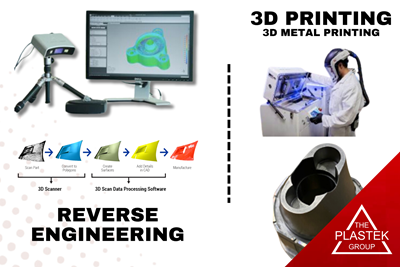

Read MoreCross-Functional Group Targets Metal 3D Printing Design, Engineering Services

NPE2024: An emphasis on reverse engineering, 3D printing and conformal cooling design capabilities brings high-quality molding and tooling concepts and processes to The Plastek Group customers.

Read MoreHybrid CAM Strategy Enables High-Quality, Efficient Mold Repair

As CAM technology requirements accelerate, and the market for additive/hybrid processes evolves, Open Mind highlights its hyperMILL for efficient repair or rework of molds.

Watch

.jpg;maxWidth=300;quality=90)