3D Printing

Optimized 3D Printer Targets Dental, Medical Applications

The new Trumpf TruPrint 1000 offers faster print speeds, higher quality parts and requires less floor space.

Read MoreCNC or 3D Printing: 5 Factors to Consider

Accuracy, time, cost, nimbleness and application considerations help to determine if a shop should use CNC machining or 3D printing.

Read MoreA 3D Printing Retrospective

A personal review of the evolution of 3D printing in moldmaking throughout the past 25 years.

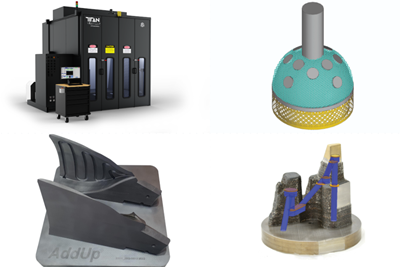

Read More3D Printing Technologies for Moldmaking Applications

3D printing technologies, from conformal cooling to complex mold building, are making an impact on the moldmaking industry, one innovation at a time.

Read MoreQualified Tool Steel Enhances Thermal Transfer, Long Tool Life

Next Chapter Manufacturing has successfully qualified HTC-45 tool steel, an optimized version of H13, to support better thermal transfer and faster cycle times for molders and die-casters.

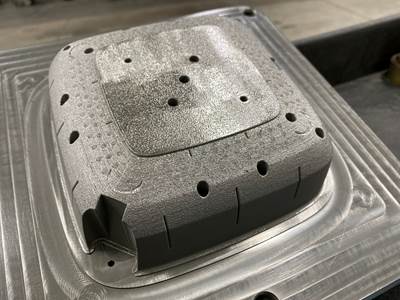

Read MorePellet Extrusion 3D Printing Raises Advantages in Thermoforming, Vacuum Forming Molds

3D Systems’ Atlas and Atlas-HS thermoplastic pellet extrusion 3D printers offer high-speed printing of molds with high-performance, high-temperature materials.

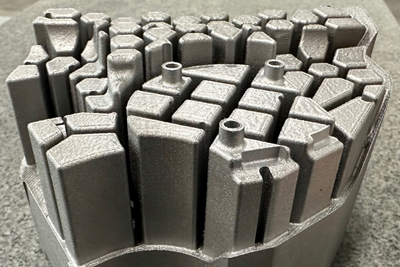

Read MoreDie-Cast Mold Conformal Cooling Achieved Through Hybrid Multi-Material 3D Printer

The DMG MORI Lasertec 65 DED hybrid combines 3D printing with milling to manufacture cooling channels in a single setup.

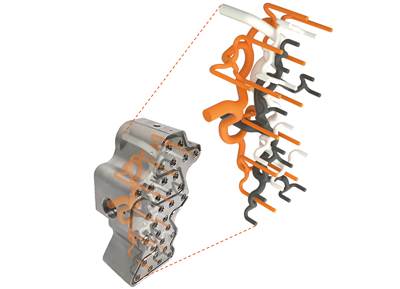

Read MoreHot Runner Manifold Offers Increased Flexibility

Hasco’s additively manufactured Steamrunner hot runner manifold allows for increased flexibility with injection molding.

Read MoreSociety of Plastics Engineers Acquires 3Dnatives, Expands Additive Manufacturing Expertise

3Dnative, a leading global media and event platform, will broaden SPE’s global reach through daily industry news and distinct market-specific platforms produced in five native languages.

Read MoreNext Chapter Manufacturing Expands Into Medical Industry, Initiates NXCMED

Additive surgical company will deliver surgical device solutions, such as implants and complex surgical devices, through disruptive design and 3D printing technologies.

Read More

.jpg;maxWidth=300;quality=90)