3D Printing

MMT Chats: 3D Printing Molds and Training Moldmakers

MMT editorial director Christina Fuges and Westminster Tool vice president Hillary Thomas sit down to discuss Westminster Tool's successful partnerships. Get to know more about Westminster Academy and how molds make the world go round. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

WatchMMT Chats: Wepco's Journey with Metal 3D Printing

MMT's Editorial Director, Christina Fuges sits down with Wepco's director of manufacturing Support, Amanda Wiriya to talk about Wepco's journey with 3D printing and how the company brings awareness to the community about the growing moldmaking industry. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

WatchEvaluating Metal Powders for Conformally Cooled Mold Inserts

Mechanical properties and design software techniques reveal the benefits of a modified high thermal conductivity metal powder for 3D printing in moldmaking.

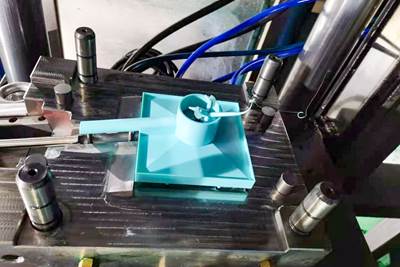

Read MoreVIDEO: How can 3D Printed Tooling Improve Injection Mold Venting?

Proper venting is one of a mold builders toughest challenges as molders struggle to keep vents free flowing in production. Learn how to apply 3D printing to mold venting and the benefits of additive venting inserts.

WatchVIDEO: How Molds Make Life Happen

Hasco America Inc.'s Engineering Manager, Brenda Clark, brings her lifelong expertise to our MoldMaking Technology audience by shedding light on new innovations, what skills are needed to be successful in the industry and how Molds Make Life Happen.

WatchVIDEO: What Does Integrated Predictive Modeling Mean to Moldmaking

Although conformal cooling is not a new concept, new technologies have made it a very hot topic, including predictive engineering models and 3D printing. Learn about a new conformal cooling process and algorithm and what it reveals about hot spots and conformal cooling design.

WatchVariable Density-Coated Tool Steel for High-Wear Molds

A mold builder can have an abundance of venting and fully dense solid areas in steel by using variable density sintering to eliminate gas trap defects in high-wear molds.

Read MoreMold in a Day Technology Slashes Tool Production, Eliminates Supply Chain Headache

Next Chapter Manufacturing says its Mold in a Day additive manufacturing technology slashes the production of tooling down to hours while maintaining the same quality and tolerance standards of conventional molds.

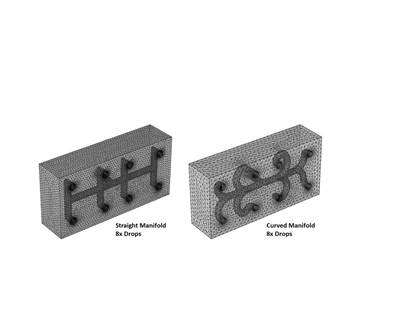

Read MoreGuidelines for Advanced Hot Runner Manifold Channel Design

Recent simulation research highlights the difference between a drilled, straight manifold channel design and a curved channel design produced via additive manufacturing.

Read MoreCutter Considerations for Hybrid Additive Manufacturing

Four tips for applying the right cutting tools in hybrid additive manufacturing.

Read More