Westfall Technik Promotes Integrated Hot Runner, Tooling Technology at Amerimold 2021

Proprietary technology from Westfall Technik produces parts ranging from 0.001 g to 400 lb and are designed for longevity and reliability.

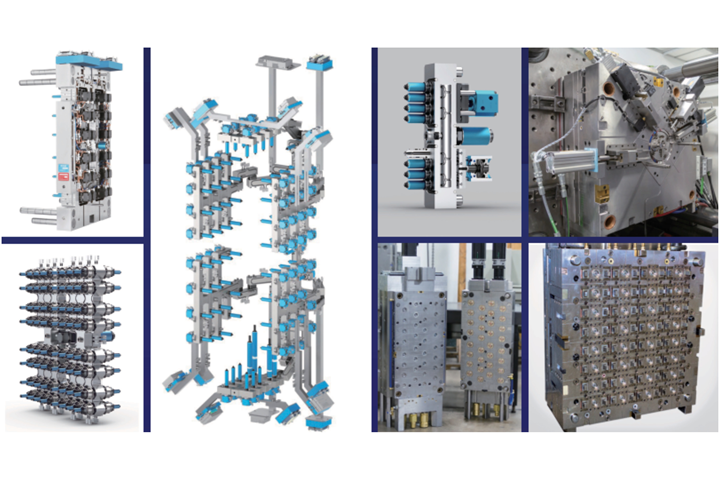

Photo Credit: Westfall Technik

Westfall Technik has developed proprietary hot runner technology to produce parts ranging from 0.001 g to 400 lb. The easy-to-maintain hot runners are designed for longevity and reliability.

At Amerimold 2021, Westfall says it will showcase compact internal valve gate nozzles; O-ring free black box actuators; removable cartridge manifolds; moving slide manifolds; angled valve gate technology; easy-to-operate star gate nozzles and multi-tip valve gate nozzles; and ISOKOR hot runner technology for micromolding.

Westfall will also promote its advanced high-precision (± 0.001”) micro molding and high-precision, high-cavitation tooling solutions with integrated hot runners. With its stacked integrated model and advanced engineering team, Westfall says it is able to help moldmakers and custom molders improve quality and reduce costs.

Exhibitor: Westfall Technik

Booth 539 (P)

Related Content

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.