Grip Vise System Easily Adapts, Conforms to Workpiece with no Preliminary Machining

FCS North America is presenting its grip vise systems at IMTS 2022, offering general metalworkers and mold builders a position accuracy of ±0.02 mm.

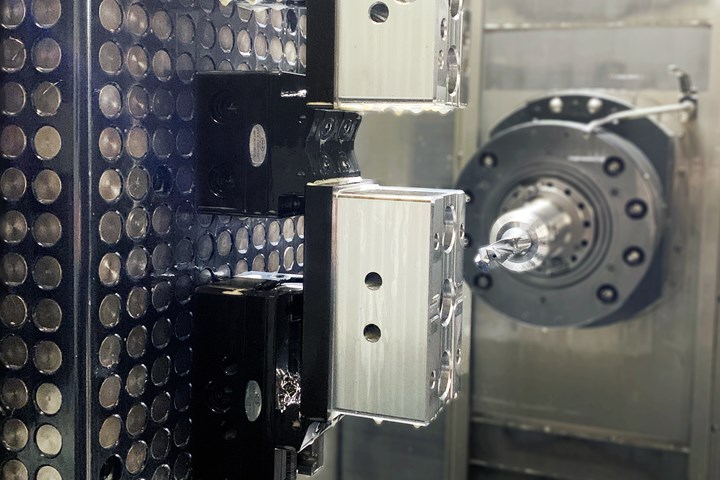

FCS North America presents grip vise systems, Mono-Sliding, Double Fix and Self-Centering clamping models, to general metalworkers and moldmakers at IMTS 2022 that requires no preliminary machining of the rough workpiece and easily clamps and centers workpieces within a position accuracy of ±0.02 mm. The Grip Vise, which has a minimal compact gripping mechanism starting at 2.5 or 5 mm, is also available to hold the part. Moreover, the forces generated to clamp the workpiece are divided between two axis lines, resulting in minimal deformation of the part, FCS notes.

The gripping jaws come in a variety of sizes and features with two interchangeable, independent inserts, providing maximum adaptability and conformity to the dimension and shape of the workpiece for mold manufacturing. Different insert types can be selected, whether for a rough, non-finished surface or finished surface application. It also enables direct setups for five-axis machining with minimal part intrusion.

According to the company, the vises can be easily positioned on an FCS M16 50-mm grid system, an M12 25-mm grid system, smaller pallet selections or raised on FCS’ body systems.

Related Content

-

Tungaloy, NTK Toolholding Solutions Improve Efficiency for Small-Part Machining

IMTS 2024: Tungaloy and NTK Cutting Tools are showcasing Swiss-type product lines designed for small-part machining, including toolholders, ceramic inserts, micro tools and more.

-

Seven-Axis Multifunction Machines Increase Accuracy for Mold Production

IMTS 2024: Cheto Corporation SA highlights its five up to seven-axis multifunction machines to increase accuracy and decrease the costs of complex mold production.

-

EOS Expands Materials Portfolio with Moldmakers in Mind

IMTS 2024: EOS North America highlights its latest industrial 3D printing solutions, including its upgraded portfolio of metal additive manufacturing (AM) solutions designed with industrial AM production in mind for industries such as moldmaking.