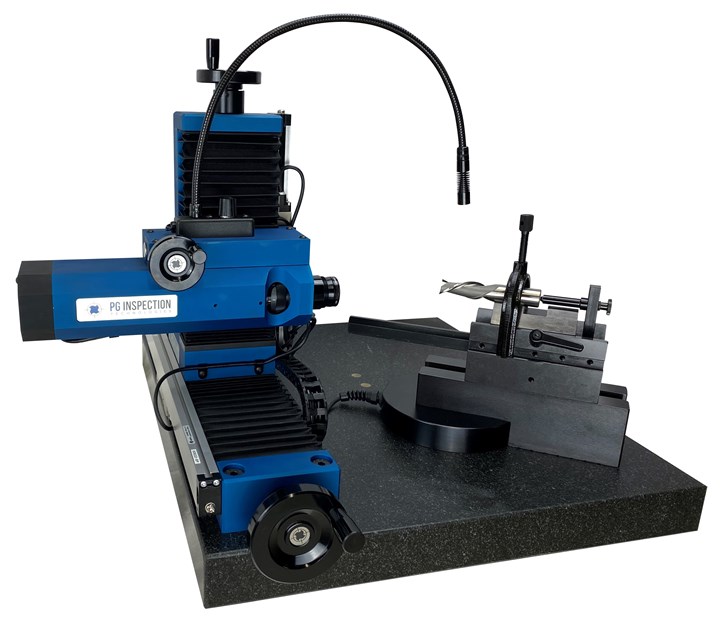

PG Inspection Tools Unveils PG1000 Optical Cutting Tool Inspection System

PG Inspection Tools will be demonstrating the PG1000, which ensures all molds and components are within the manufacturer's specifications, at Amerimold 2021.

Photo Credit: PG Inspection Tools

The PG1000 optical cutting tool inspection system to be demonstrated at Amerimold 2021 by PG Inspection Tools ensures that the cutting tools used to manufacture molds or any other parts are within the manufacturer's specifications. The PG1000-200 and PG1000-400 models, specifically, are durable and easy-to-use systems that allow the user to take tool geometry measurements down to the micron level. Most measurements take less than 30 seconds.

According to PG Inspection Tools, little training is necessary to operate the PG1000 and the included REACTION software. The company recently released version 9 of the software, which features a simplified user interface and the addition of new calculation instructions, demonstration videos and a manual. A new reporting feature is said to enable users to easily create fully customized PDF reports, which contributes to more efficient moldmaking. The user experience and the stability of the software are also improved in this latest version.

Exhibitor: PG Inspection Tools

Booth 348 (P)

Related Content

-

Software Strategy for Automated Mold Inspection

Consider inspection software with a CAD/CAM platform that supports model-based definition, works with all CAD files, and drives all fixed and portable CMMs.

-

CT Scanning Helps Micro Molder Reduce Cost of First Article Inspections

CT scanning services performed by 3D ProScan, a division of NyproMold Inc. provides MTD Micro Molding with accurate, high-resolution internal and external measurements performed about seven times faster and at significant cost savings.

-

2024 Moldmaking Insights: A Year in Review Part 1

A look back at the top moldmaking trends of 2024, as revealed through MMT's analytics. This review highlights the most popular technical articles, case studies, tips and best practices that captured the industry's attention over the past year.