Online Training Program Devotes a Comprehensive Approach to Injection Molding

Kruse Training offers a range of topics for new and veteran engineers, including Mold Design, which focuses on the basics of mold design and how various design elements impact a molded part.

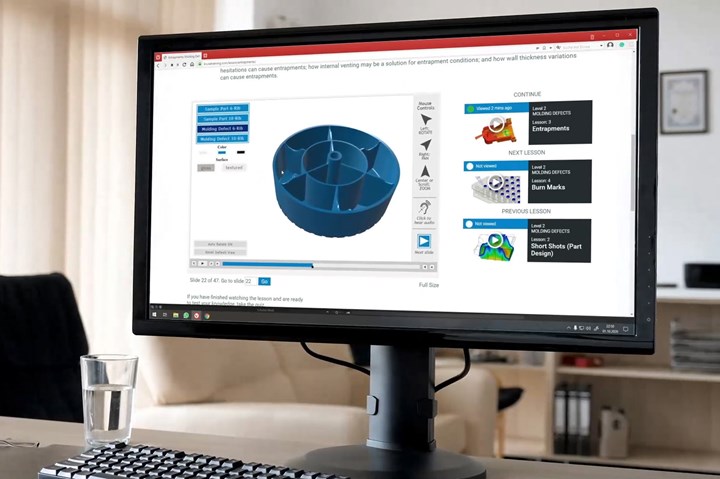

Photo Credit: Kruse Training

The “Circle of Knowledge” offered by Kruse Training is a holistic method that teaches the cause-and-effect behavior in injection molding, helping engineers become all-around molding experts. Kruse Training is an online program that provides an overview of how injection molding professionals, from entry-level to experienced engineers, can benefit from this comprehensive approach. Lessons contain real-world examples of molding scenarios that show how to integrate the training materials in the real world. The Kruse Training method is aimed at helping develop synergistic teams of cross-trained professionals who can successfully design and mold plastic components.

While Kruse Training’s online program covers a range of topics, the company specifically focuses on its Mold Design section, which is devoted to the basics of mold design and how various design elements impact a molded part. The mold design section includes lessons on gate design and placement (such as understanding and utilizing industry best practices for gate types, placement options and size), cold runner systems (optimizing cold runner shapes and sizes to make pressure drops, polymer shearing, packing and cooling behavior, gate sealing time and overall cycle time are more efficient) and cooling (understanding the thermal behavior of polymers and the pathway of heat inside a mold).

Explanations, simulations, cause-and-effect analyses and the uses of various design features are covered in this section. Understanding these design features is important because they influence the moldability, function, appearance and quality of a part, Kruse Training says.

The company notes that a Mold Design lesson on mold steel selection is currently available at its website at no charge.

The video below shows a Mold Steel Selection webinar from June 10, 2021 with topics that cover the most common mold steel materials and what attributes they should possess; the best mold steel options for different polymer materials, injection pressures and production cycles; and temperature distribution behavior for molds with different mold steels and mold components.

Related Content

-

How to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

-

Tackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

-

Making Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.