Moldmaker/Molder Adds Consumer Order Fulfillment Service

Best Tool & Engineering works closely with manufacturing engineers, inventors and product developers to turn their concepts into reality, providing customers cost savings and full, turnkey services.

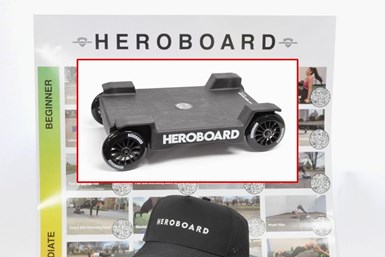

The Heroboard, QR exercise poster, hat, yoga blocks, extra heavy black band, red workout band and backpack. Not shown: Custom exercise pad that fits over top of the Heroboard. Source | Best Tool & Engineering

Best Tool & Engineering (BTE) is an ISO 9001:2015-certified, full-service moldmaking and injection molding company, based in Clinton Township, Michigan, that has added a new service to its repertoire: consumer order fulfillment.

Best Tool points to the Heroboard, a physical fitness product, as a prime example of this service. What began as a design consultation with Donald McIntyre, inventor of the Heroboard, has grown into complete production of the product. This includes tooling, molded parts, pad printing, assembly, packaging, warehousing and drop-shipping of the product, providing complete order fulfillment. It also involves handling orders for accessories and promotional items (supplied by the customer) and shipping, along with the Heroboard (backpacks, hats, etc.).

BTE’s design engineers took previous models of the Heroboard — it was a prototype at the time — and modified the design to optimize for manufacturability. Then they built the 7075 aluminum mold from ground up, including the mold base; it features a single cavity, with two slides and modified designs.

Notably, 99% of BTE’s customers (new and existing) engage the company during the design phase of their projects. BTE’s team of engineering, design and manufacturing specialists work closely with manufacturing engineers, inventors and product developers to turn their concepts into reality.

BTE employs 15 full-time team members. Capabilities include design and engineering, injection molding (66-500-ton presses), vibration and hot plate welding, transfer tooling, pad printing, product assembly and distribution/drop shipping.

Tool building for plastic injection molding includes prototype, short run and production molds. BTE also provides machining services (milling, drilling, turning and wire EDM) for low- to high-volume production.

Markets served include (but are not limited to) medical equipment, consumer durables, consumer and B&B electronics, and alternative energy.