Modified Composition Enhances Stainless Steel Capabilities

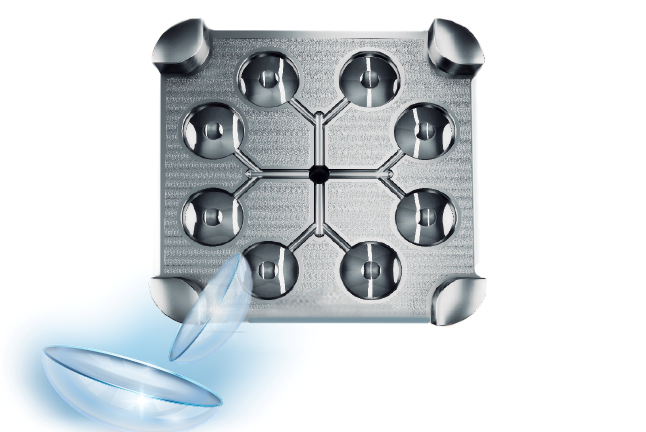

Edro introduces Böhler’s M333 Isoplast stainless steel which has been manufactured via a new melting technology for best-in-class polishability, conductivity, toughness and corrosion resistance.

Photo Credit: Edro Engineering

Edro, an exclusive U.S. distributor for Böhler, introduces the company’s newly developed M333 Isoplast stainless steel. Manufactured via a new melting technology, M333 offers moldmakers what is said to be best-in-class polishability, enhanced thermal conductivity, optimized toughness and exceptional corrosion resistance.

According to Edro, testing has shown M333 Isoplast to exhibit up to four times the toughness levels seen in 420 stainless steel and almost matching the toughness of H13. This enables molds to have the benefits of stainless steel without the risk of cracking.

M333 Isoplast’s chemistry and pressure electroslag remelting process also provides M333 enhanced thermal conductivity almost matching H13, ensuring faster cycle times up to 20% compared to traditional 420 ESR.

Further, the stainless steel’s primary and secondary carbides are significantly reduced by lowering the carbon content and optimizing chemical composition, Edro notes, resulting in improved microstructure. Combining this with M333’s P-ESR remelting process results in improved finishes and faster polishing times.

Finally, M333’s modified alloying composition improves corrosion resistance by reducing carbides and improving the free chromium within the steels matrix. M333’s double remelting process ensures a homogenous microstructure to give provide exceptional corrosion resistance.

Related Content

-

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

-

Advantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.