Large Mold Builder Builds Strategic Alliances

Cavalier Tool & Manufacturing builds about 200 quality molds per year, aided by new technology investments, an experienced team and strategic alliances sought with customers and suppliers.

Photo Credit: Cavalier Tool & Manufacturing

Cavalier Tool & Manufacturing is a global mold manufacturer established in 1975 with 220 employees throughout Canada, Latin America, India and the U.S., designing and building mid- to large-size molds. This mold builder’s Windsor, Ontario 66,000-square-foot facility houses technology that builds about 200 molds per year for 250- to 4,000-ton presses. Cavalier builds injection, structural foam, gas assist, multi-shot, thermoset, prototype or compression molds for the automotive, commercial, recreational, medical, heavy truck and agricultural industries. With a worldwide customer base, including numerous Fortune 500 companies, Cavalier says it strives to develop strategic alliances with customers and suppliers.

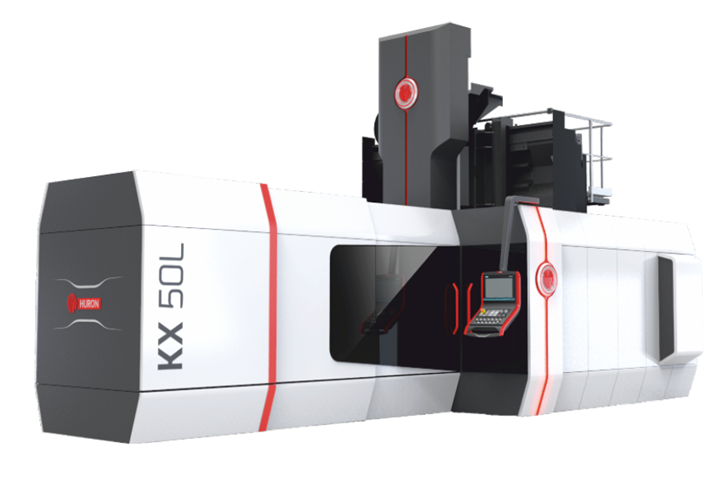

The Cavalier team reportedly designs and builds a quality mold, on time and at a competitive price. Further, Cavalier says its mold building expertise enables the company to produce parts or tooling in a very short period of times. The latest equipment purchase was a second Huron KX 50L, a large five-axis CNC bridge mill for the tool and mold industry, configured as a double-column machine for fast, high-accuracy machining of complex parts. Added to its expertise is the acquisition of Mold Services International.