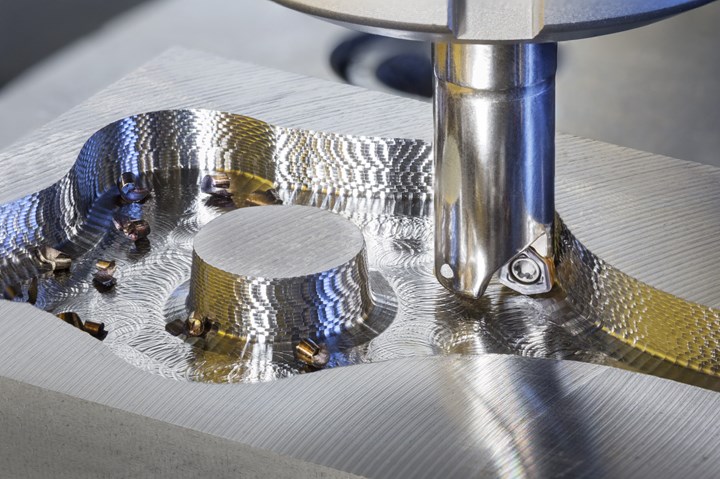

Indexable Tools Intended for Rough Milling Small Diameters at High Feed Rates

Iscar USA presents the Micro3feed family of end mills, which are designed to target compact parts, small-in-size cavities, pockets and more with a range shank configurations, lengths and material types.

Photo Credit: Iscar USA

Iscar’s new family of Micro3feed indexable tools have been designed to replace solid carbide end mills. Intended for the productive rough milling of compact parts, small-in-size cavities, pockets and more at high feed rates, Micro3feed is applicable in die and moldmaking—such as small, closed forging dies and intricate blow molds that have deep contours—and the manufacture of miniature parts and small components, among other applications.

With a shallow cutting-edge angle and shank stiffness, the Micro3feed platform is able to perform on large L x D ratios—which solid round tools are not typically designed for—a particularly desirable feature when resinking a die after weldment. The platform is also combined with Iscar’s Multi Master connection with a range of shank configurations, lengths and material types for enhanced versatility.

Micro3feed comes in four different grades optimized for ISO P (steel, ferritic and martensitic stainless steel), ISO K (cast iron), ISO S (high-temperature alloys) and ISO H (hardened steel and cast iron).

Related Content

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

.png;maxWidth=300;quality=90)