High-Speed Spindle Series Harnesses High Coolant Pressures for Small Cutters

Tungaloy launches the iteration of its HPC SpinJet line, an easily adaptable tool which uses coolant pressures of up to 70 bar (1,015 psi).

Photo Credit: Tungaloy America

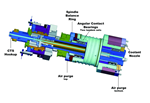

Tungaloy America highlights the expansion of its SpinJet coolant-driven, auxiliary high-speed spindle series to include the HPC SpinJet line which uses coolant pressures of up to 7 MPa (70 bar, 1,015 psi).

Easily adaptable to the spindle of existing CNC machines, the SpinJet provides instant enhancements in machining performance using small diameter cutting tools. No additional machine purchase or modifications are required; the SpinJet utilizes the machine’s existing through-spindle coolant supply as a pressurized power source to drive the internal turbine for cutting tool rotation, eliminating the cost and trouble of external air or electric power supplies. Tungaloy says this feature gives the SpinJet a compact and smart design, allowing it to be stored in a machine’s ATC or tool magazine when it is not being used and installed on the main spindle as with any other standard tool.

In addition, the SpinJet includes a wireless display monitor giving operators real-time performance of RPMs for optimal cutting tool conditions according to actual rotational speed on the workpiece.

The new HPC SpinJet harnesses higher coolant pressures in a range of 4-7 MPa (40-70 bar, 580-1,015 psi), rotating the turbine as fast as 45,000 RPMs. With enhanced internal turbine and bearings for higher torque output, the HPC SpinJet can handle various rotating tools in up to 3 mm in diameter.

According to Tungaloy, HPC SpinJet boosts productivity when compared with conventional spindle setups, eliminating the need for workpiece transfer and maintaining an intact process chain for better machine downtime and operation efficiency.

Six new models, including TJSHPCBT40, TJSHPCER32, TJSHPCHSKA63, TJSHPCCAT40, TJSHPCC6 and TJSHPCST20 have been introduced.

Related Content

-

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

-

3D Printing Enables Better Coolant Delivery in Milling Operations

Just like 3D printing enabled conformal cooling channels in molds, additive manufacturing is now being used to optimize coolant delivery in cutting tools.

-

Products and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

.png;maxWidth=300;quality=90)