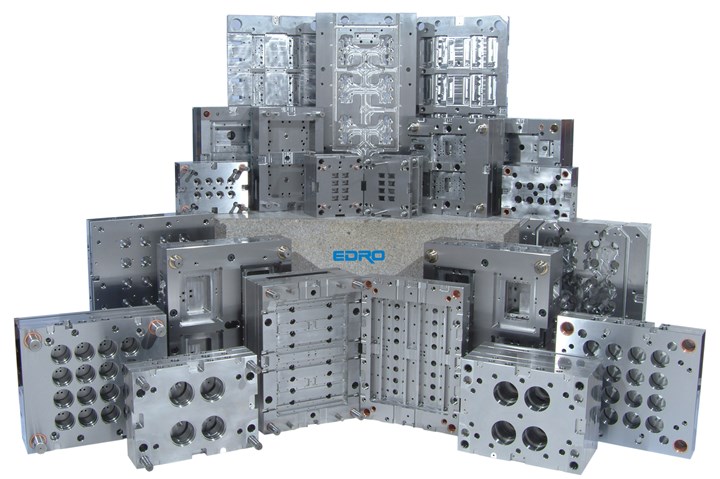

High-Cavitation Custom Mold Bases Ensure Precise Alignment

Edro produces a variety of high-cavitation custom mold bases under temperature-controlled environments and close inspection for complete accuracy and precision.

Photo Credit: Edro

Edro Engineering and Specialty Steels Inc. showcases its specialization in the manufacture of high-cavitation custom mold bases, designed to demonstrate precision alignment and long-lasting performance. Edro primarily produces high-cavitation stripper molds, stack molds, super structures, spin-stack molds and hot runner bases, as well as auto unwind and runnerless mold bases to exacting tolerances.

The company says it employes many quality control techniques to further enhance the accuracy of its work. For example, the entire finish-machining department is housed in a temperature-controlled environment to minimize plate and machine movement as final mold base tolerances are completed for product accuracy. The company also inspects all critical plates and locations in a temperature-controlled inspection room, regulated to ± 1º of the desired mark, and laser calibrates each machine on a regular basis. These steps, says Edro, are to ensure that each feature on its mold plates are at their true location, traceable to the U.S. Bureau of Standards.

Moreover, Edro recently invested in precision machining equipment, further enhancing efficiency and the company’s capabilities.

Related Content

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

-

The Secrets to Hard Milling Success

The Secrets to Hard Milling Success

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.