Full-Support Mold Builder Delivers High-Precision, Performance Tooling Systems

Customers rely on Dynamic Tool Corp.’s comprehensive array of engineering capabilities, experience, and complete staff and resources to deliver everything from new product development to preventative mold maintenance.

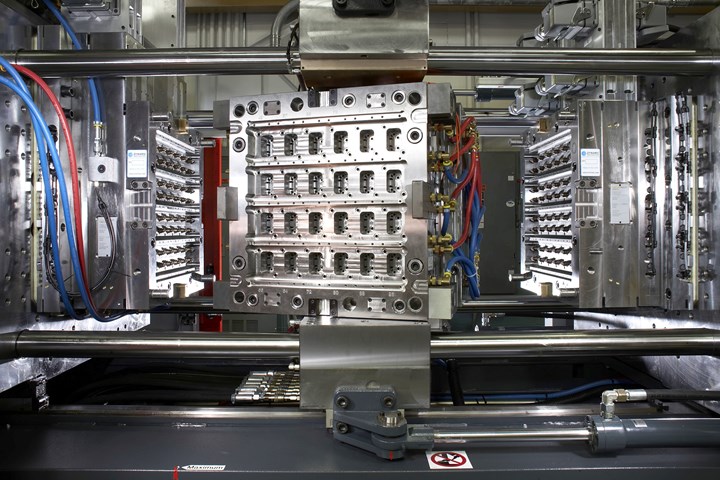

Dynamic Tool Corp. specializes in the design and build of high-performance tooling systems for medical/pharma device, personal healthcare, packaging and industrial markets. Its customers rely on the company’s experience and innovative engineering to create multishot, collapsible core, living hinge/in-mold close, insert, in-mold decorating, thin wall injection molds, stack, rotary stack and rotary spindle tooling systems. Dynamic Tool’s expansive and diverse machining processes (traditional subtractive and 3D print/additive machining) are said to combine sophisticated equipment with inline metrology to repeatably produce validated steel. Mold productivity and performance are the company’s core deliverables, regarding thermal design, conformal cooling and mold uptime.

Dynamic’s mold processing and sampling capabilities cover applications spanning 22-650 tons, from one to three-shot processes, with complete ancillary equipment support, including robotics/end of arm tooling (EOAT), custom controllers, conveyors and personnel support for downstream value-added operations.

Dynamic Tool is staffed and resourced to fully support new product development for customers, from engineering and design-for-manufacturing (DFM), to comprehensive process simulation, to the fabrication, validation and launch of custom turnkey manufacturing cells. The company says it will effectively and efficiently handle any NPD needs, supplying single-cavity prototype molds to four-cavity developmental bridge tooling to multiple sets of high-cavitation productions molds. Its engineering team is a progressive group of engineers, with strong backgrounds in part and mold design, toolmaking and process development.

The company also supplies preventive mold maintenance (PM) and repair services via a dedicated PM team, supporting basic cleaning and inspection to complete refurbishment of injection molds.