Flexibility, Maintenance Support is Made Available for Machine Tending Line

To further aids its customers purchasing the LoadMate Plus, Mitsubishi Electric Automation enables flexible connectivity, servicing for both robot and CNC and a maintenance and warranty program.

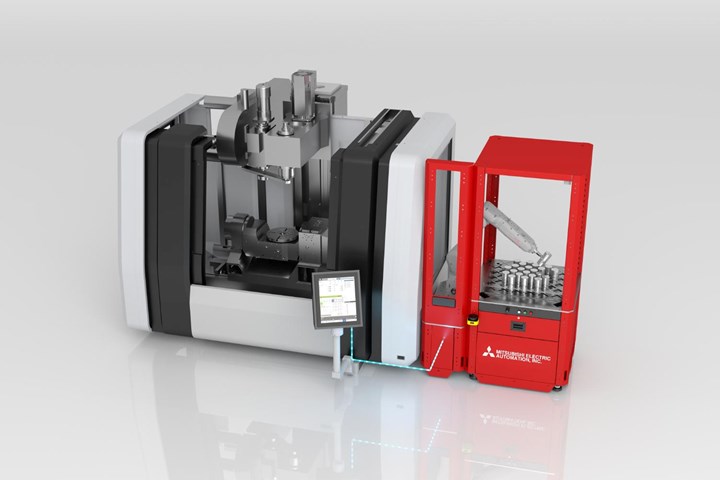

Mitsubishi Electric Automation’s LoadMate Plus machine tending line is engineered for easy setup, flexibility and mobility, while addressing labor shortage challenges and the pressure to maximize productivity. Machine tending, the process of loading and unloading parts or materials into a machine tool center, is often a key component that enable unattended or lights-out machining operations for mold manufacturers, and gives employees the opportunity to work on duties of greater value in the shop.

Through flexible connectivity via Ethernet and easy programming through the direct robot control (DRC) feature of Mitsubishi Electric’s M8 series, machine tending can benefit customers that may not have experienced

robot programmers available. In addition to DRC, almost any CNC machine

can be connected to a shop floor via discrete I/O for non-M8 CNC

controls from Mitsubishi Electric and other companies. Further support

is available through Mitsubishi Electric trained engineers to service both

robot and CNC. Additionally, Mitsubishi Electric Automation offers a 5-

year robot maintenance and warranty program.

According to Mitsubishi’s website, the LoadMate Plus is “completely configurable. The robot and stand are perfect for standalone cells, or to be integrated into a larger solution.”

Related Content

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

-

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.