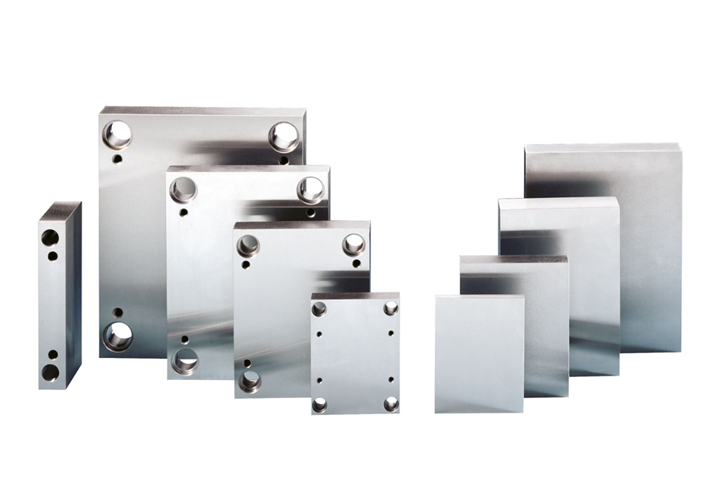

Extended mold plate range increases customer flexibility

More than 2,000 drilled and undrilled plate variants from Hasco enable the development and production of injection molding, pressing and die-cast tools.

Share

Hasco announces the expansion of its mold plate range to around 2,000 variants of undrilled P-plates and drilled K-plates, promoting standardization as well as increasing the flexibility requirements of modern moldmaking. Hascos says its plates offer an optimal combination of simplicity, precision and availability, achieving cost-effectiveness.

The company’s P- and K-plates are machined on all sides and can be combined for the development and production of injection molding tools. Each plate is created with precision and high surface quality, made from low-stress European quality steel. In addition to a high level of plane parallelism, the mold plates are said to be tailored to modern manufacturing techniques.

In addition to their modular design and their variety, K-standard parts are either designed to the nominal size for direct use or have an allowance for subsequent heat treatment.

Several thousand stress-relieved panels are permanently available from stock.

Related Content

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.