EDM, Precision Milling Technologies Highlight High-Precision Features for the Moldmaking Industry

MC Machinery Systems features a range of wire and sinker EDMs, machining centers and automation at IMTS 2022.

MC Machinery, a subsidiary of the Mitsubishi Corp., showcases its latest EDM and precision milling technology, including wire and sinker EDMs, machining centers and automation, at IMTS booth #338129.

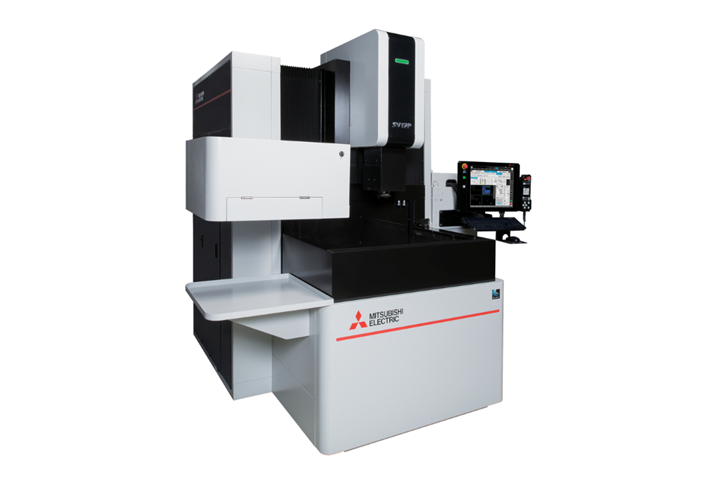

Newly featured sinker EDMs include the Mitsubishi SV12P and SG12 and Gantry Eagle 800. The former features mAIsmart IDPM3 (Intelligent Digital Power Master Control), which uses a state-of-the-art sensor to monitor the total amount of electrode contact area within the workpiece, so the system can automatically changes power conditions based on real-time measurement feedback to produce the most efficient burn. This results in up to 40% less electrode wear and up to 30% reduction in machining time for moldmakers.

Alternatively, the Gantry Eagle 800 is reported to be best in class for large-part and molding applications, featuring low electrode wear and fast cycle times. It also has a large, easy-to-access working area that requires less floor space than other sinker EDM models.

Wire EDMs showcased include the MV1200-R Mitsubishi submerging threading, fiber optic machine communication and power supply technology; the MV2400-R Mitsubishi for a wide range of applications, featuring a larger tank capacity and low operational costs; the MV4800-S Mitsubishi, ideal for large-part applications up to 20" high (standard), 32" high (optional) and submerged cutting up to 20" deep; and the MX600 Oil Advance Plus for micro machining, with wire capability down to 0.0008″ (0.02 mm) diameter and surface finishes down to 1.6µ Ra.

Precision milling machines on the show floor involve the Roku HC658II with high graphite protection for high-precision manufacturing and mold industry customers; the Android II linear drive milling machine designed for very precise, hard steel and carbide machining with accuracies within ±1µm; and the Ingersoll Eagle V550 graphite machining center featuring high-speed, high-precision five-axis machining for small graphite electrodes and mold/die components.

Related Content

-

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

-

Integrated CAD/CAM Streamlines Electrode Manufacture, Improves Quality

A focus on electrode design and automation helps toolroom improve efficiency, reduce tooling costs and deliver higher quality products.

-

Collaborative Engineering Drives Quality Mold Solutions

Advanced engineering and tooling teams collaborate to train, design, develop and deliver high-quality, cost-effective molds efficiently, ensuring perfect parts and faster launches.