Cobot Software Update Adds and Improves Operational Features

The line of 0B7 collaborative robots from Absolute Machine Tools’ partner Productive Robotics have been enhanced with 50 additional operational and ease-of-use features.

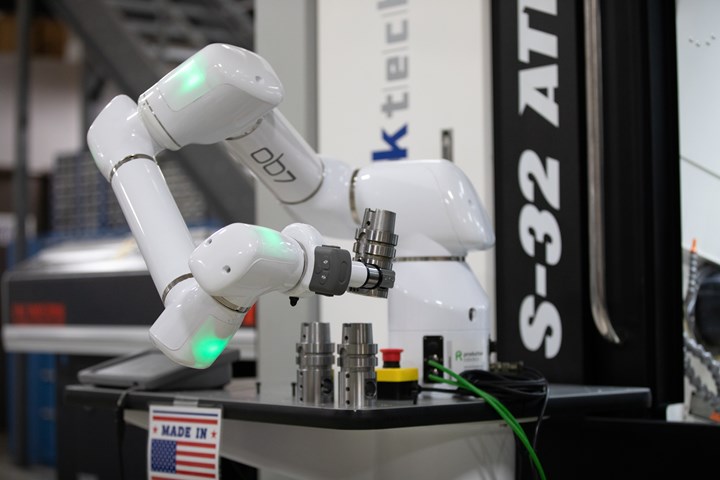

Photo Credit: Absolute Machine Tools

New software updates are said to add 50 operational and ease-of-use features to the line of OB7 collaborative robots from Absolute Machine Tools’ partner Productive Robotics, a company developing next-generation collaborative robotics technology. The software updates enhance the cobots’ connectivity, expedite efficient integration with other equipment and facilitate real-time status monitoring.

According to Absolute Machine Tools, included in the list of new and upgraded features is full linear control that broadens the cobots’ “no-programming, no coding,” simple-to-teach intelligence. The updated software is also said to strengthen the cobots’ ability to directly monitor and control the machines they work with, including providing instant connection to equipment with Rockwell Automation’s Ethernet IP. Live online monitoring with email and text alerts enable real-time updates and notifications of machine stoppages or other issues. Further, complete interoperability with Cognex and other smart camera systems expedites systems integration.

With seven axes, the company notes that the OB7 cobots have extended flexibility that enables them to reach around obstructions and operate in confined workplaces. The family of four different OB7 cobots is engineered to accomplish simple to complex tasks for various payloads and sizes. Absolute Machine Tools also points to the benefits of fast, reliable technical support and part supply services, as a result of the cobot’s manufacture in the U.S.

Related Content

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

-

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.