CNC Additive Simulation Ensures Moldmaking Component Quality and Accuracy

CGTech’s VERICUT software features an additive module that simulates both additive and traditional milling or turning capabilities, including material deposition.

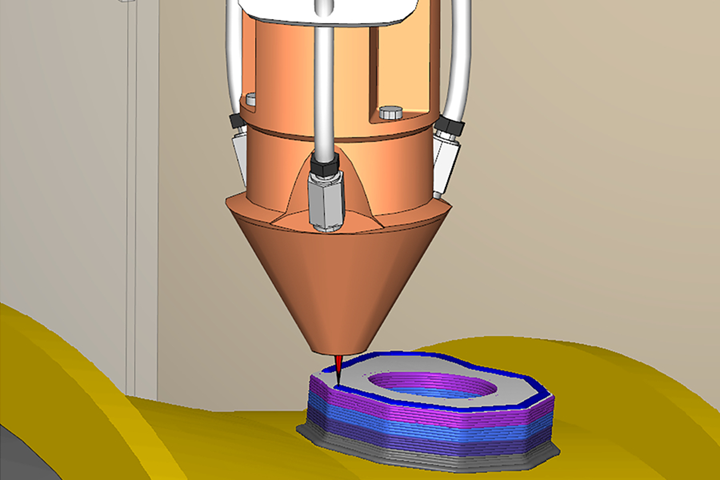

Photo Credit: CGTech

CGTech’s software, VERICUT, features an additive module that simulates both additive and traditional milling or turning capabilities of hybrid CNC machines. VERICUT’s simulation safeguards both the machine and the component from damage by detecting potential collisions, validating laser, material and gas usage, as well as identifying errors throughout the additive process. Droplet technology offers optimized simulation of material deposition, which is easily distinguished from cut stock or existing material. Each droplet also contains history information which can save time when investigating errors such as voids or excess material. The simulation allows for easy comparison between the finished part and its intended design to ensure the quality of the completed part.

VERICUT’s additive module also works in conjunction with Force, a physics-based optimization module to ensure components are machined using optimal methods for the given material and within safe operating limits of the CNC machine and any cutting tools. Force charts show the details of an optimized milling operation with feed rates automatically adjusted to maintain a constant and ideal chip thickness, resulting in better surface quality finishes.

Related Content

-

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

-

Fundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.