CAD/CAM Software Updates for Mold Design and Manufacturing

TopSolid USA’s TopSolid’Mold digital design and manufacturing solution offers mold and die makers new features and improvements related to conformal cooling, organization and identification.

Share

Read Next

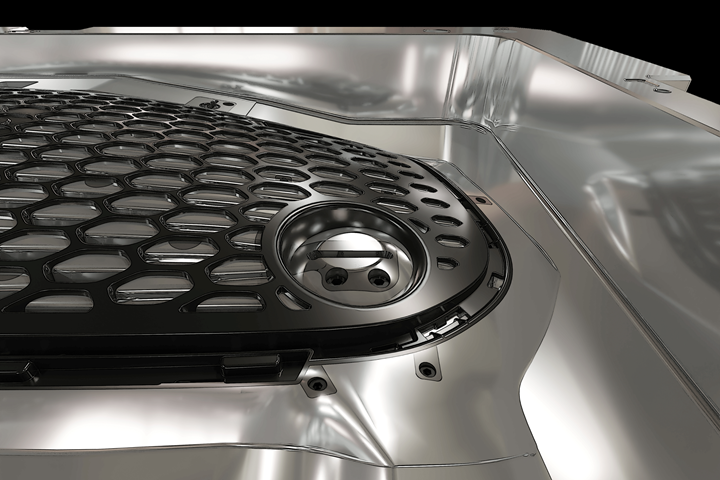

TopSolid USA exhibits new updates to TopSolid’Mold, a complete CAD/CAM solution for moldmakers and tool and die specialists that is reported to halve the time taken to design a mold. Grouping together TopSolid’Progress and TopSolid’Electrode integrated modules, TopSolid’Mold covers the complete digital design and manufacturing chain. The software easily works with customer data, easily repairs, adapts and edits data, uses both industry standards and user-designed components, takes into account material deformations and retraction, simulations tool mechanics and more, according to the company.

TopSolid’Mold offers users several new improvements. A new quick view bar is available to optimize organization, greatly facilitating consultation and visualization of the various parts associated with the tooling (presses, handling parts and more). The installation of angular pins has been simplified by an automated graphic cross section when defining and adjusting the component. This new feature makes for better understanding

and speeds up the design of moving elements, TopSolid says. Cooling circuits can be improved now that any shape can be managed. The company says this feature enables complex cooling circuits to be quickly defined as close as possible to the plastic part in order to optimize cooling.

Additional highlights include a new marking command for easier engraving

of text and properties on various parts of the mold (plates, cavities, et cetera), and a Pin Markings feature that can be used to (a) easily identify the pins by applying a marking on the head (manufacturing index) and (b) identify the housing of the pin on the ejector plate, thereby minimizing the risk of errors

during assembly.

Related Content

-

How to Manage Wall Thickness Changes in Your Mold Design

To ensure even filling and cooling, consider wall section transitions, corners and fillets, ribs and bosses, lip and rim designs and CAE flow simulation software.

-

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

-

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.