CAD/CAM Software Equips Moldmakers with New Features, Functions

Cimatron v16 introduces new and enhanced capabilities to equip toolmakers across the spectrum to deliver high-quality tools faster and easier.

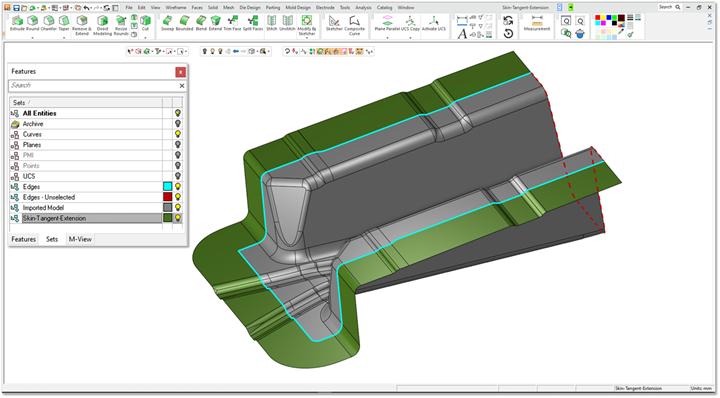

Cimatron presents its v16 CAD/CAM software release at IMTS 2022, introducing new and enhanced capabilities to equip toolmakers across the spectrum to deliver higher quality tools — including molds, dies and electrodes — faster and easier.

Cimatron 16 is said to expands NC automation with several important features. Three-axis Rough & Volume Pocketing now supports automatic selection of multi-cutters of different lengths to achieve less tool vibration and faster speeds. Milling pockets of multiple heights and depths is now a one-step routine with the redesigned Pocket Manager. Plus, Cimatron says, users can copy and paste geometry between procedures, as well as import cutters, holders and extensions directly from external data interface files (STEP & IGES) from tool suppliers.

Cimatron 16 introduces several machining strategies including five-axis undercutting, geodesic three-axis and a new 2.5-axis slotting procedure that uses pre-drilled holes in order to speed up machining with the optimum tools. In addition, new Automatic Drill modes are able to run via NC template for a reportedly seamless creation of hole groups, and also account for unique stock shapes for safer, faster machining.

Moldmakers specifically benefit from a new Ejector Lock function, Parting Surface Skin Tangent extension and better control of conformal cooling channels. For die designers, Addendum Faces functionality was revamped to handle complex forms. The company adds that making electrodes is easier with Electrode Wizard and EDM setup enhancements.

Moreover, Cimatron 16 presents a cleaner UI with many added CAD features, such as automated rib creation, volumetric text, Sketcher for reference drawings and new dimensioning. Dynamic Triad feature enable programmers to position and adjust components with live Drag & Preview. New commands such as Print-by-Batch, add Time Stamps to BOM Assembly, and Search Preferences provide a better experience overall.

Cimatron is exhibiting alongside GibbsCAM in the Machinery Hall booth #338880 as key partners in the Sandvik Design and Planning Automation.

Related Content

-

Tungaloy, NTK Toolholding Solutions Improve Efficiency for Small-Part Machining

IMTS 2024: Tungaloy and NTK Cutting Tools are showcasing Swiss-type product lines designed for small-part machining, including toolholders, ceramic inserts, micro tools and more.

-

EDM-3 Graphite Enables Moldmakers to Meet Strict Precision Requirements

IMTS 2024: Entegris Poco Materials highlights its EDM-3 graphite, known for exceptional strength, wear resistance and fine surface finish characteristics and thus an ideal solution for moldmakers’ most demanding applications.

-

Zeiss Upgrades CMMs to Support Sustainability

IMTS 2024: Zeiss highlights upgrades to its Prismo family of CMMs, designed to reduce power consumption and support sustainability.