Angle Pin Holder Simplifies Installation and Removal from Parting Line

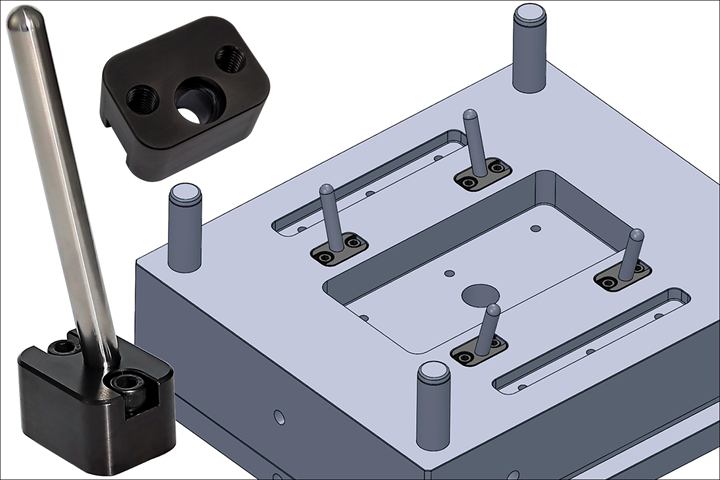

Progressive Component’s angle pin holder is designed to avoid angled machining, eliminates the need for long angle pins or bored holes and does not require the mold to be removed from the press.

Photo Credit: Progressive Components

Progressive Components introduces a new angle pin holder engineered to simplify the installation and removal of angle pins.

For the mold builder, Progressive’s angle pin holder is designed to avoid angled machining, and on large A plates, it eliminates the need for long angle pins and long bored holes. For the molder, removal of broken angle pins from the parting line is said to be simple, and unlike other approaches, does not require the mold to be removed from the press.

Manufactured with AISI 4140 steel and black oxide treated for corrosion resistance, the angle pin holder is offered with 10°, 15° or 20° angles for 3/8, 1/2″, 5/8″ and 3/4″ diameters. There are 23 sizes of a single in-line bolt configuration and an additional 23 sizes with two bolts for when space is limited behind the angle pin (shown above).

For additional convenience, Progressive’s angle pins can be ordered with the radius machined to the final length required.

Related Content

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

-

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.