All-in-One Wire-Laser Metal 3D Printer for Mold Manufacture, Maintenance

Meltio’s M450 system is designed for industry without the need for industrial, providing application versatility from industrial prototyping to mold and die to cladding and repair.

Meltio seeks to bring affordable wire-laser metal 3D printing systems to a variety of end markets — automotive aerospace, machine shops, railway, military, naval, mining and more — for applications across industrial prototyping, mold and die, one-offs, short runs, mass manufacturing, maintenance, cladding and repair.

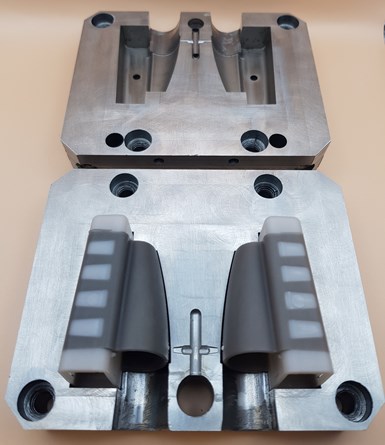

One machine, Meltio M450, for example, is a turnkey directed energy deposition (DED) solution that integrates wire dispensing technology on a three-axis Cartesian system in a closed enclosure. Reliable and inexpensive, the company says it is the machine suitable for additive metal manufacturing of medium parts and molds. It is an all-in-one AM solution for repairing, laser cladding, laser welding, laser cutting, laser texturing and polishing.

Meltio M450 can produce complex metallic components from wire feedstock with stainless steels, Inconel, Invar, titanium and other tooling materials. Using a wire laser is said to optimize operation and material handling, ensuring 100% material efficiency.

The M450 was applied to an EU project, imPURE, which aimed to develop a methodology to reuse existing pilot lines for manufacturing medical materials through design and development of modular molds for injection molding. Additive manufacturing (AM) company Conify used the Meltio M450 to study different process parameters for the manufacture of mold inserts for oximeters, ultimately verifying the quality of the DED molds and the overall methodology for rapid tooling manufacturing.

Related Content

-

3D Printing Technologies for Moldmaking Applications

3D printing technologies, from conformal cooling to complex mold building, are making an impact on the moldmaking industry, one innovation at a time.

-

Building Molds: Most Popular Reads of 2024

Dive into the most-viewed content for building your mold, including topics such as cutting tools, EDM, hot runners, additive manufacturing, mold materials, machining and mold components.

-

3D Printing Enables Better Coolant Delivery in Milling Operations

Just like 3D printing enabled conformal cooling channels in molds, additive manufacturing is now being used to optimize coolant delivery in cutting tools.