All-In-One CAD/CAM System Streamlines Mold, Die and Model Design and Manufacturing

Tebis 4.1 from Tebis America enables manufacturers to automate the design and build process, while improving safety, efficiency and quality.

Photo Credit: Tebis America Inc.

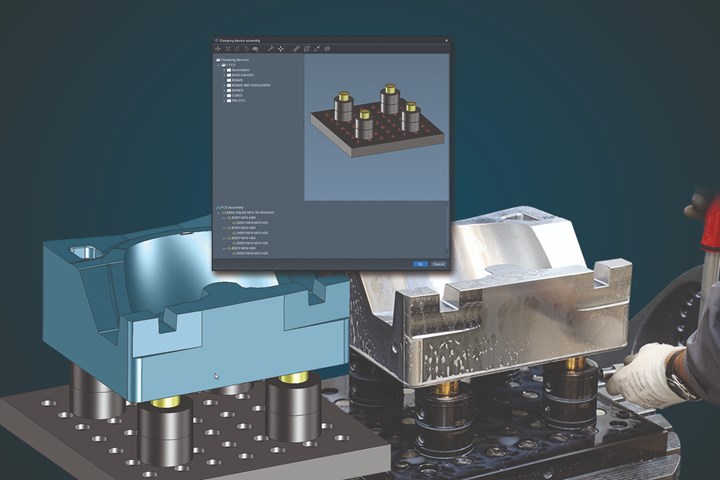

Tebis America Inc. has launched Tebis 4.1, a complete parametric-associative CAD/CAM system, which is said to provide seamless, highly automated mold, die and model design, development, programming and manufacturing in a single system.

The software platform is built on input from infield designers, for an intuitive and user-friendly structure. Additionally, Tebis 4.1 integrates measuring and production, resulting in shorter setup and machining time, higher component quality and fewer correction iterations. Finally, safety is improved by providing more flexibility to non-verified virtual machines to prevent potential collisions.

The software itself is said to retain a robust CAD hybrid system that combines free-form surfaces and solids. The newly developed parametric-associative system base has been specifically adapted to requirements of single-part and small-series manufacturing. In contrast to many other volume-based systems, the company says Tebis 4.1 doesn’t distinguish between surfaces and open or closed solids, allowing all objects to intersect without creating error messages. Additionally, similar to the CAM environment, templates can be used to structure and standardize CAD activities.

Automation capabilities have also been increased. The 4.1 platform provides users with all necessary prerequisites for safe and efficient production. The ProLeiS MES software is fully integrated so manufacturing can be automatically planned, controlled and executed. As an integration platform, ProLeiS can also be easily combined with upstream and downstream systems such as PDM, ERP and machine control systems.

Further, a clamping device library supplements the virtual process libraries where details of the real manufacturing components are represented in the form of digital twins. The clamping device library can be used to conveniently create and manage clamping elements and clamping device groups and to set up the machine in the virtual environment. All relevant information is transferred with the NC documentation to the person responsible for setup.

Tebis 4.1 also offers user guidance. Job Manager and Tebis NC Job technologies, for example, enable the creation and management of NC programs for all technologies needed to manufacture a component. The Job Manager, located in the CAM node, also is said to reflect the entire manufacturing process with clearly structured operating sequences and logically guides the user through CAM programming.

A personalized user interface can be individually configured and precisely adapted to specific tasks and requirements and can be used as templates for company-wide standards.

Related Content

-

Quality Tool & Die Enhances Performance With Advanced EDM and Milling Technologies

The adoption of Mitsubishi wire and sinker EDMs, along with the OPS Ingersoll five-axis milling machine with automated cells, has enabled unmanned operations and improved precision. As a result, QTD has expanded its facility, grown its workforce and increased its business by 10-15% annually.

-

Five-Axis Graphite Mill With Automation Debottlenecks Electrode Machining

Five-axis electrode cutting enabled Preferred Tool to EDM complex internal screw geometry on an insert that otherwise would have had to be outsourced.

-

CAM Automation Increases Mold Production, Quality

Mold builder switches CAM software package after 20 years to take advantage of innovative programming strategies that reduce mold machining programming and processing times.