Abrasives for the Final Finish, Repair of Hardened Tools

CNB stones, diamond Ceramic Super Stones and other specialty stone solutions offered by DW Sales are designed to easily cut hardened tool steels and welds.

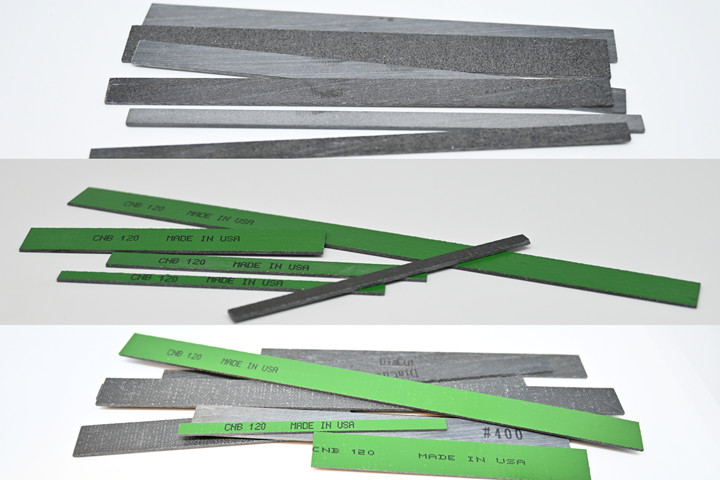

Abrasive solutions, including diamond ceramic stones (top), CNB stones (middle) and specialty stones (bottom). Photo Credit: DW Sales

Often, during the final finish and repair of hardened tools, common abrasives just don’t “cut it,” according to DW Sales. The company provides specialty stone solutions designed to cut through 55 Rockwell hardness and higher to meet these surface treatment needs, including CNB stones and diamond Ceramic Super Stones.

The CNB stone, comprising fine ceramic fibers encased in glass and sandwiched into a stick form, easily cuts hardened tool steels and welds. It is commonly used in an air profiler, like the UTR-70. However, DW Sales notes that caution needs to be used with this abrasive technique, as CNBs can cut deep and fast. Once the high spot of the weld is close to removed, the surface finish can be blended in with finer diamond super stones.

Diamond Ceramic Super Stones are available from 180 to 600 grit and in three widths. Comprised of a ceramic fiber impregnated with diamond grains, DW Sales says these finer stones make finishing hardened steel and/or harder welds an easier task.

Related Content

-

Breaking Down 3D Scanning in Moldmaking

Identifying 3D scanning requirements and implementing the appropriate technology.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

What Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.