A Virtual Reality Solution for Injection Molding Training

Virtual reality courses for injection molding training are under development by Molding Expert LLC, aiming to prepare trainees for work on an actual shop floor.

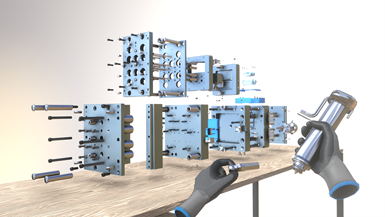

Virtual reality has become mainstream for many industrial applications, enabling users to explore, learn and prepare for new technologies. Molding Expert LLC is developing a fully functional molding facility VR training solution. The goal is to create virtual reality courses for the injection molding industry, teaching users how to become “VR molding experts” and prepare for working on an actual shop floor.

The initial phase of Molding Expert training focuses on two areas. The first enables users to have the ability to explore a typical molding facility with audio guidance. For the second area, mold designers and moldmakers are able to use the VR technology to examine and analyze some standard mold designs.

Courses are being developed to help molders to work effectively on a molding floor and to review detailed mold designs. The second phase of training expands to other areas of molding, providing engineers with the skills and confidence to advance to the next level of real-world molding challenges.

The current areas of research and development for Molding Expert include Tool Design Review and Molding Facilities. Tool Design Review enables users to review and learn about mold designs early in the process. Molding Facilities enables users to explore a typical molding floor in a virtual space.

The Molding Expert facility is a custom built virtual molding factory. The design of each space is based on a typical real-world functional molding facility to create the most realistic virtual experience possible.

The Molding Expert VR training tool is being developed to help attract the next generation of leaders and thinkers to the injection molding industry. Torsten Kruse, founder and president of Kruse Analysis and Kruse Training, is applying his experience and knowledge of the industry to create this distinctive training solution that can be utilized across various sectors.

Related Content

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

The Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

-

MMT Chats: The Connection Between Additive Manufacturing Education and ROI

This MMT Chat continues the conversation with Action Mold and Machining, as two members of the Additive Manufacturing team dig a little deeper into AM education, AM’s return on investment and the facility and equipment requirements to implement AM properly.