3D CAD Software Release Ensures Manufacturing Agility and Efficiency

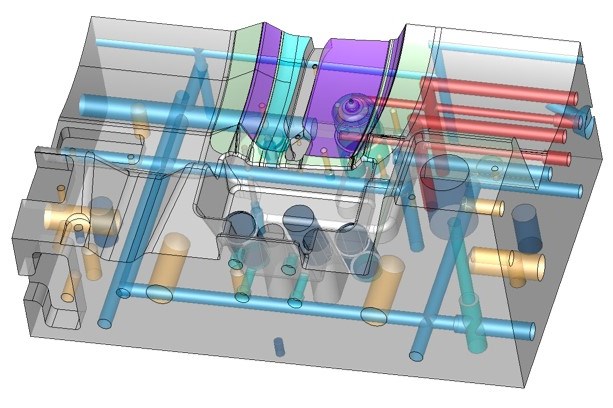

Enhanced model-based definition capabilities including improved color tools, expanded proprietary readers for STEP files and more round out Kubotek3D’s KeyCreator MfgCAD software.

Photo Credit: Kubotek3D

The 2021 release of Kubotek3D’s KeyCreator 3D CAD software, KeyCreator MfgCAD, is designed to maximize productive re-use of CAD data. An efficient and agile manufacturing tool, the software provides improvements to model-based definition (MBD) capabilities, productivity enhancements to various functions and updates to CAD translators.

According to Kubotek, for complex tooling design, face color attributes on the 3D model are commonly used as a form of MBD to signify manufacturing information such as surface tolerance and hole type. These colors are later converted to cycle parameters in the NC program. When this process can be automated, it follows the strategy called preserving the digital thread. With KeyCreator MfgCAD, the materials system has been enhanced in this area to better support definition of what each face color means and quickly apply or copy those colors to appropriate faces. Compared to manual labor, the concept saves time and errors.

Since specific colors have different meaning for different shops, KeyCreator 2021 now stores material definitions in design and template files and allows loading and saving sets of materials from configuration files. An update to the selection filtering system enables quick access to faces with a specific material from any function. To extend support for design data from any source, KeyCreator 2021 recognizes unique face colors on imported models and automatically creates matching material definitions. This feature speeds up the process of defining a standard set of colors to be used on future jobs headed to a specific shop.

Kubotek proprietary readers for STEP (ISO 10303) files have also been expanded to cover AP 242 to support customers using a full, standard-based MBD approach. STEP AP 242 defines critical manufacturing annotations including Geometric Dimensioning and Tolerancing (GD&T) and their relationship to the faces of the 3D model. These annotations and the nominal size and position of the precise geometric model provide an unambiguous part definition. This form of MBD provides process efficiency by eliminating the need to translate the design into detail drawings and better support automation of downstream activities such as NC machining and inspection.

Further, a second STEP enhancement has been added to the 2021 release to open and export compressed ASCII STEP files which use the extension “.stpZ”. Compressed STEP files are around 20% of the size of uncompressed STEP files.

KeyCreator 2021 offers other productivity improvements including auxiliary drawing views defined perpendicular to a line/edge; significant speed improvement re-opening the Detail Style Editor; axis indicators selectable for vector direction or position; and creation of a 2D section slice geometry from part reference geometry.

Interoperability with other CAD software has also been updated with the latest versions of two major CAD file formats, Autodesk Inventor 2021 and PTC Creo 7.0.

A complete list of translation features in KeyCreator 2021 can be found here.

Related Content

-

How to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

-

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

-

Tolerancing in Mold Design, Part 2: Using GD&T to Address Conventional Tolerancing Issues

Mold designers can achieve a single interpretation of workpiece functionality when following the American Society of Mechanical Engineers Geometric Dimensioning and Tolerancing standard.